Thermoplastic polymers become pliable or moldable above specific temperatures and return to a solid state upon cooling. How can this benefit your application when it comes to hose, tube and fittings...

Thermoplastics offer many advantages over thermoset rubber materials.

Thermoplastics - Compact, Light Weight, Long Life

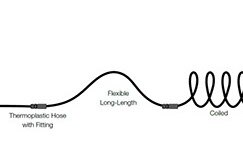

Continuous Length

Continuous Length

The manufacturing process of thermoplastic hose allows for long continuous lengths due to the material being “cured” on the line and a self-supporting core tube. Rubber hoses require a secondary curing process and a mandrel to hold the core tube dimensions. Parflex® and Polyflex have made continuous lengths of 3200m in the past - important for off shore oil applications (umbilicals). For hose assembly locations, the long lengths mean less scrap and fewer reel changeovers during production.

Small Inner Diameter (ID)

Small Inner Diameter (ID)

Because thermoplastic hose/tube manufacturing does not require a mandrel for support of the core tube, hoses can be made to extremely small inner diameters such as 1.3mm. Since rubber hoses require a mandrel, the inner diameter of rubber hoses typically stops at 4.8mm. This is important in applications where only a small amount of fluid needs to be transferred.

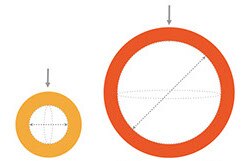

Compact Outer Diameter (OD)

Compact Outer Diameter (OD)

The inherent strength of the thermoplastic materials used to make hose allow the use of less material when compared to rubber hose. The outer diameter of thermoplastic hose from Parflex® and Polyflex can be 20% smaller than outer diameters on comparable rubber hose. This feature is very important on equipment where space is limited and many hoses must fit into a small area.

Weight (per Foot)

Weight (per Foot)

Thermoplastic hoses, due to the material and construction,

are almost always lighter than comparable rubber hoses. With Parflex® and Polyflex XDT products, low pressure rubber lines can be replaced with thermoplastic tubing that is 70% lighter.

› Continuous Length

› Inner Diameter (ID)

› Outer Diameter (OD)

› Weight

Specification Advantages

Performance Advantages

› Abrasion

› Cleanliness

› Pressure

› Permeation

› Shelf Life

› Noise

› Value

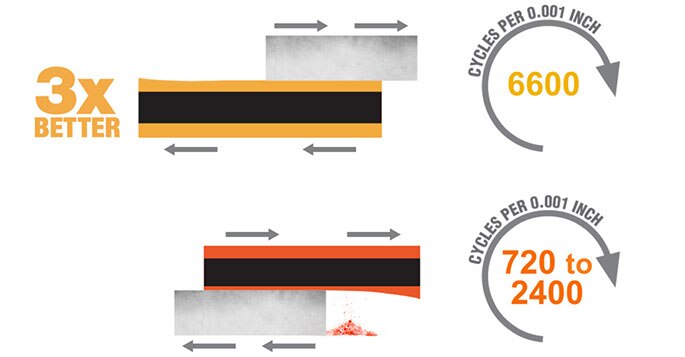

Abrasion Resistant

Many thermoplastic materials are inherently abrasion resistant. In fact, most rubber hose manufacturers add thermoplastic to hose covers to increase abrasion resistance of their hoses. Parflex® and Polyflex hoses with polyurethane covers have proven, through testing, that it takes 3 times the cycles to rub through .001 inches of cover when compared to competitive rubber hose that is touted as abrasion resistant.

Thermoplastic

Rubber

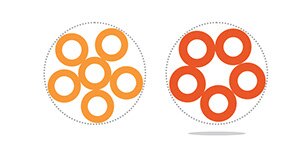

Cleanliness

The above pictures compare the contamination levels, after manufacturing, of a thermoplastic hose and a rubber hose. As seen in the pictures, the manufacturing of thermoplastic hose produces far less contamination than rubber equivalents. In many cases, the assembly of rubber hose will require cleaning of the hose prior to production use.

Thermoplastic

Rubber

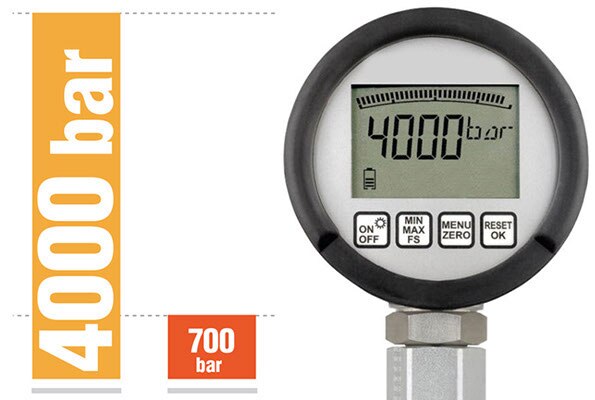

Working Pressure

Through the use of various hose reinforcement methods, Polyflex can manufacture hoses that can endure 4000bar (58,000psi) working pressures. Most rubber hose manufacturers stop at 700bar (10,000psi).

Thermoplastic

Rubber

Permeation Resistance

Through the use of various thermoplastics the permeation resistance (ingression and egression) can be far greater than rubber. As seen in the chart thermoplastic has superior permeation resistance against gases like CO2, Oxygen, and Nitrogen in comparison to rubber.

Shelf Life

Under optimal storage conditions, fluoropolymer-based thermoplastic hose and tubing products should have unlimited storage life prior to initial usage. However, optimal conditions are required (contact Parflex®/ Polyflex Technical Services for more information on optimal conditions). Per SAE J517, Rubber Hose is acceptable for 10 years if stored under optimal conditions.

Thermoplastic

Rubber

*Per SAE J517 - Hose, in bulk form passing visual inspection and proof test, shall be acceptable for use up to and including 40 quarters (10 years) from the date of manufacture. Shelf life of thermoplastic and polytetrafluoroethylene (PTFE) hose is considered to be unlimited. Hose assemblies that pass inspection and proof test shall not be stored for longer than 2 years.

Noise Reduction

Thermoplastic hoses with specific reinforcement have been shown to reduce noise on machines. This is important to operator comfort and environmental noise pollution. Please contact Parflex®/Polyflex for more information and a technical paper on this reduction.

Added Value

Thermoplastic hoses offer a wide variety of added value. Thermoplastic hoses can be thermally formed into specific shapes, the cover can be made from various colors, laylines can be modified for specific customer requirements, hoses can be bonded into multiline “ribbons” up to 10 hoses wide, and the formulation can be changed to make the hose more conductive or nonconductive.

Thermoplastic

√ Thermal Forming

√ Color Coding

√ Custom Laylines

√ Bonding

√ Conductive/Nonconductive

Rubber

The Parker Advantage

Where to Buy

Catalog 4660

Catalog 5162E

Catalog 4150-55D

Katalog 4460-DE

Find Parflex® Products

Locate a distributor of Parflex® Hose, Tubing and Fittings.

.jpg)

Catalog 4660

Parflex® Thermoplastic and Fluoropolymer Products

Hose, Tubing, Fittings and Acccessories

Catalog 5162E

Fluoropolymer Hose and Fittings

Flexible Braided Hose

Catalog 4150-55D

Fluoropolymer Extrusions

Fluid Handling and Electrical Insulation Products

Parker Hannifin

PARFLEX DIVISION

1300 N Freedom Street

Ravenna, OH 44266

USA

Ph: 330 296 2871

Parker Hannifin GMBH

POLYFLEX DIVISION EUROPE

An Der Tuchbleiche 4

Lampertheim Huettenfeld

Germany 68623

Tel.: +06256810

Fax: +0625681100

© 2017 Parker Hannifin Corporation