THE WINE INDUSTRY

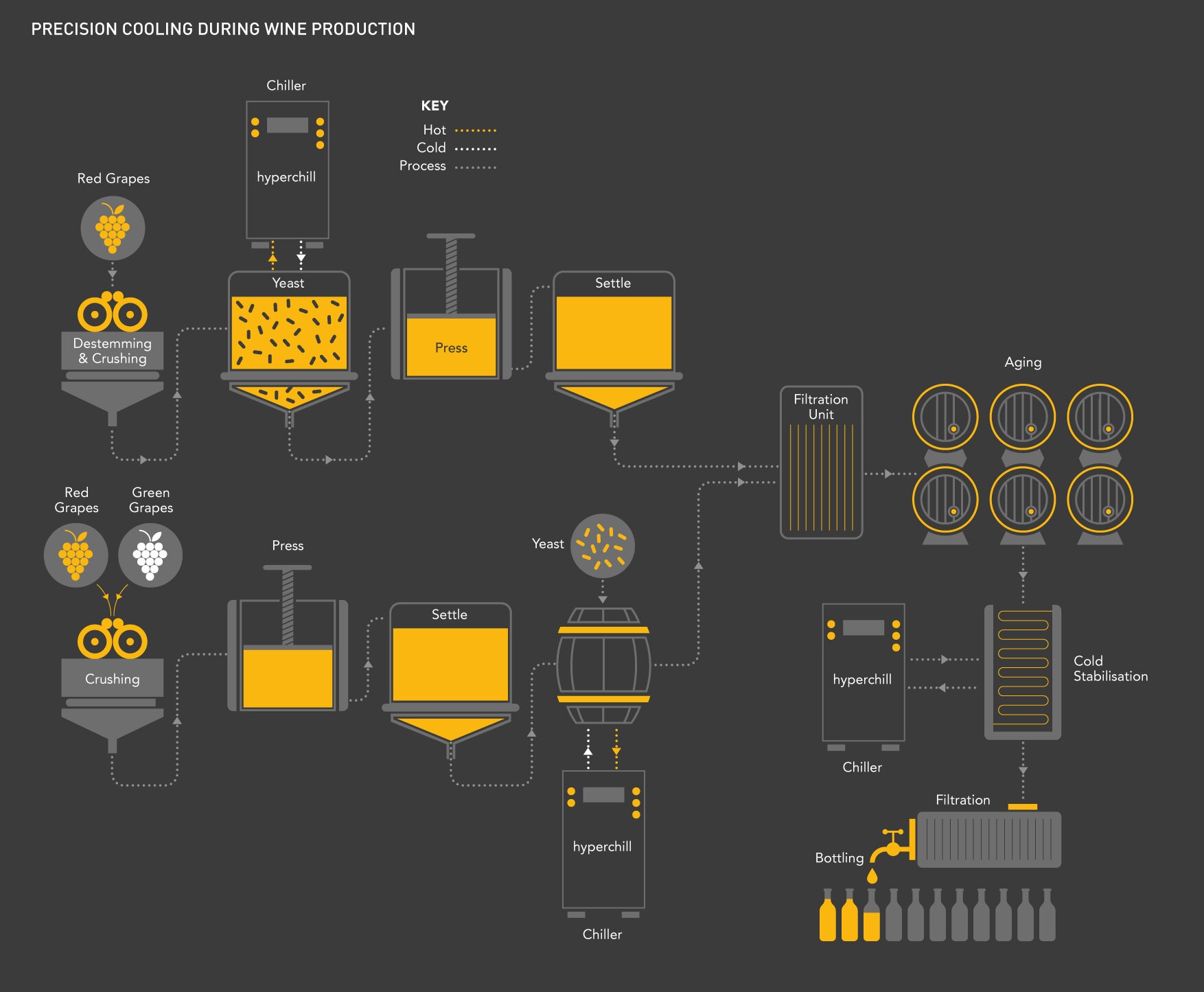

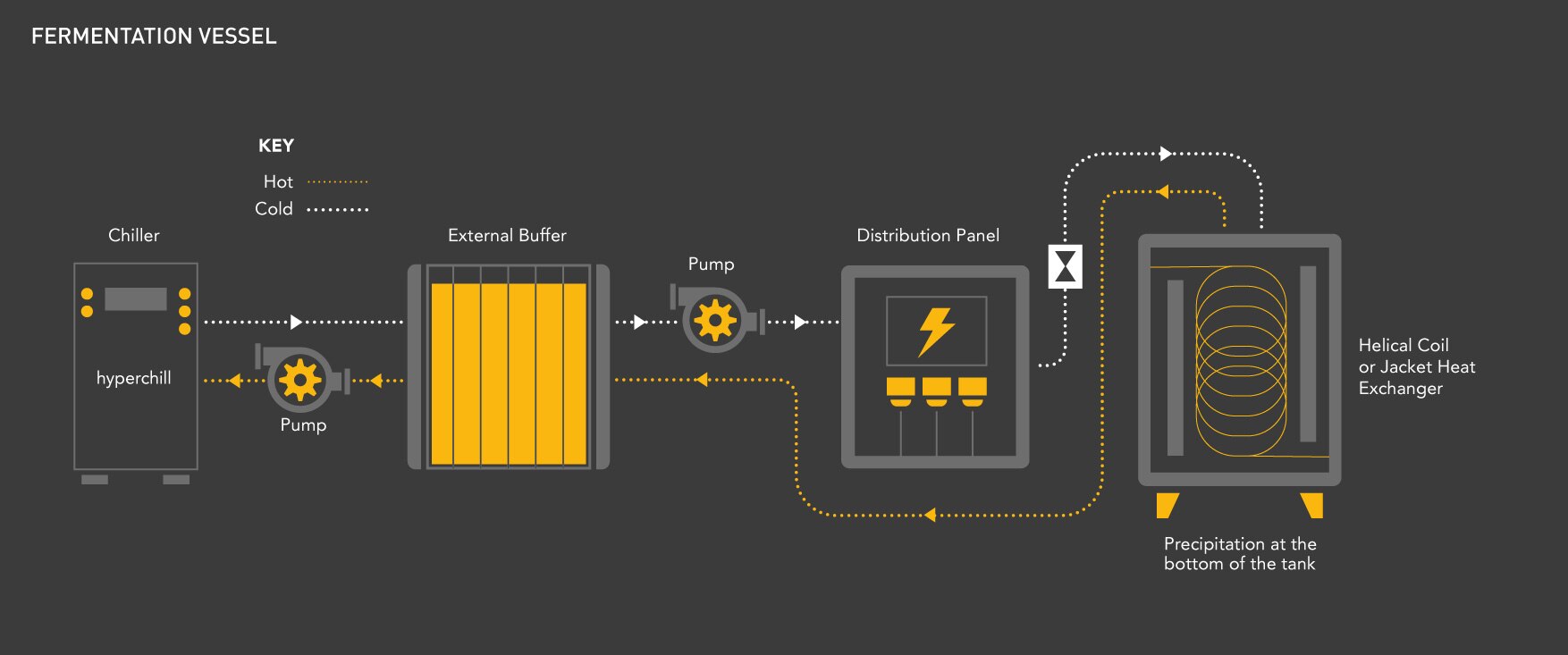

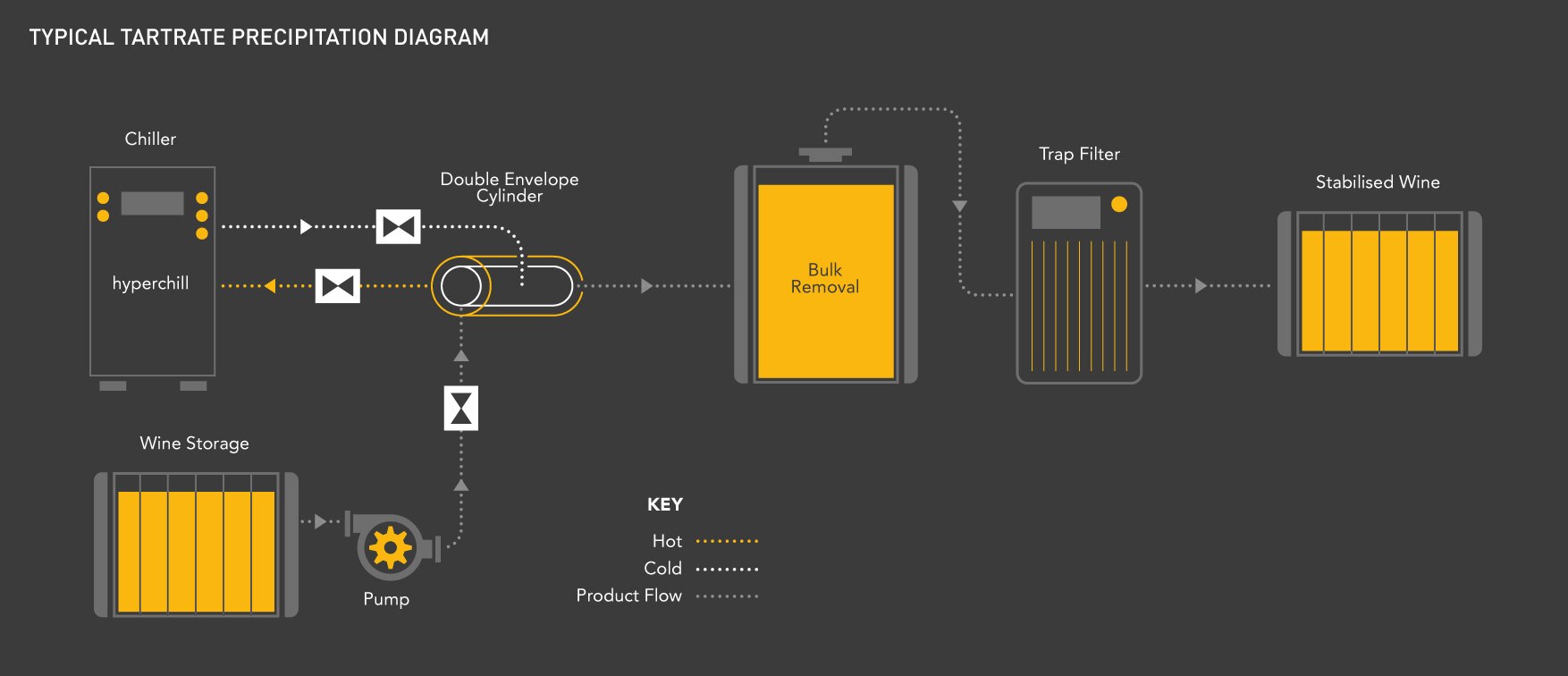

Global wine production & consumption continue to flourish. Record production levels of 293 million hectolitre were reached during 2018. Europe continues to dominate wine production with Italy, France and Spain accounting for approximately 51% of global production. Precise process cooling is one of the most critical requirements in modern winemaking. The application of cooling during several production steps facilitate high volume production whilst maintaining the unique flavour profile of the final product. Temperature control is also an important factor in wine preservation where consistent quality is required to allow distribution of the product to the global market. Hyperchill and Hyperchill Plus chillers offer a robust and cost-effective solution ideally suited to the exacting cooling demands of the wine industry.