Plastic is one of the largest and most important markets for process and precision cooling, and is a critical success factor in the production of formed plastics. Precision temperature control ensures the following:

- Dimensional stability of the plastic product

- Enhanced quality of the finished product

A failure to provide sufficient cooling can result in surface flaws in the finished product. Examples include: blistering, roughness, structural defects and opacification.

The most common forms of plastic processing that require precision cooling are:

- Injection Moulding

- Extrusion Moulding

- Blow Moulding / PET Forming

The Hyperchill and Hyperchill Plus chillers offer an ideal solution for the plastics market, providing a “one-package” solution to meet the customer’s needs

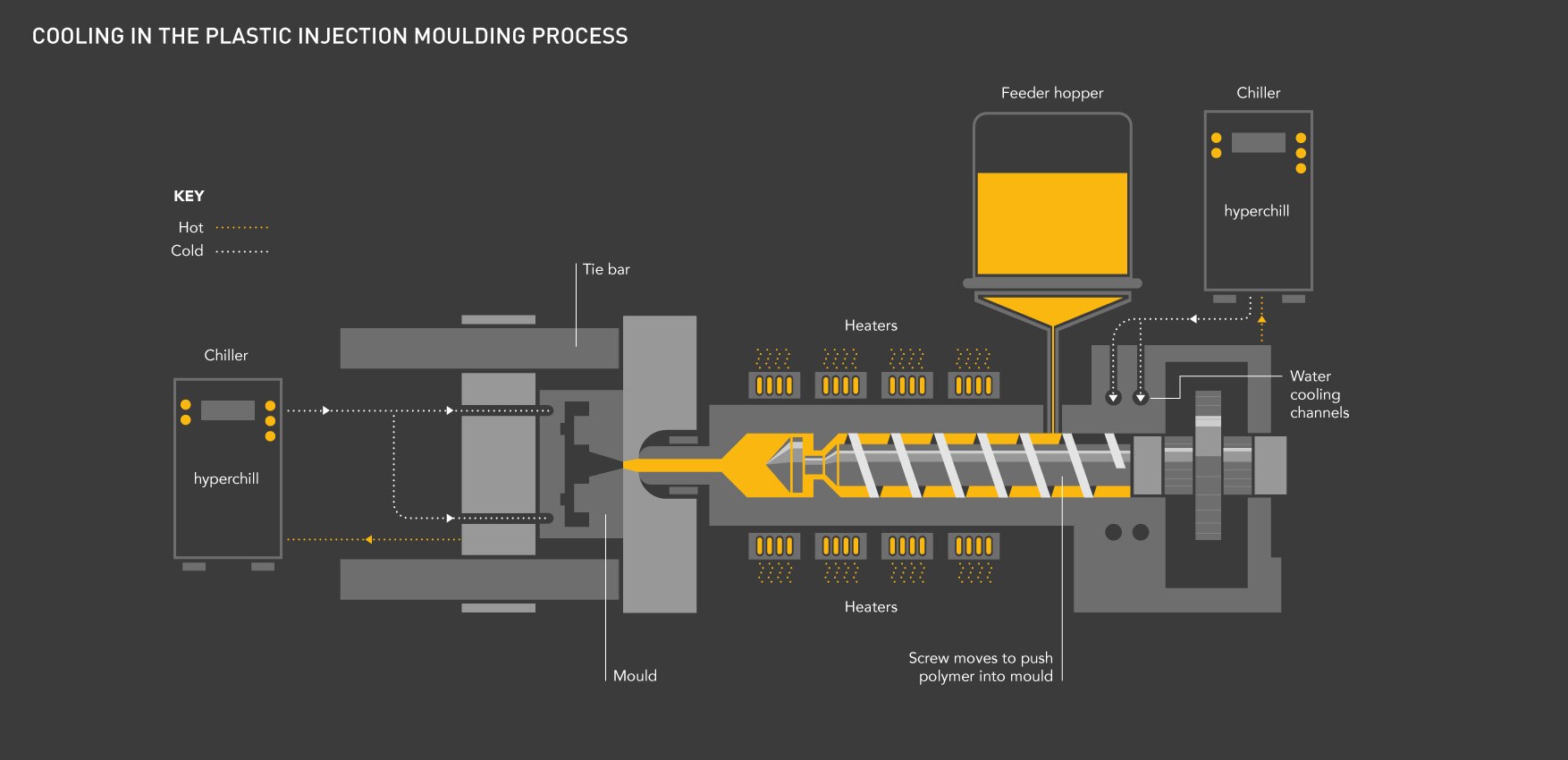

COOLING IN THE PLASTIC INJECTION MOULDING PROCESS

The injection moulding process accounts for a significant proportion of all plastic products manufactured globally. Injection moulded products range from electrical switches, wheelie bins, to complete car dashboards. The process is compatible with both thermoplastic and thermosetting plastic material. Commonly used materials include: polystyrene, ABS, polyamides, polypropylene, polyethylene and PVC. Almost all manufacturing sectors use injection moulded parts in some form.

The following diagram depicts a typical injection moulding machine:

Cooling is essential to the process and is used for the following purposes:

- Cooling of the mould to reduce cooling times prior to ejection of the finished product from the machine

- Removal of heat load from the machines hydraulic motor system used to drive the mechanical parts

INJECTION MOULDING - COOLING OF THE MOULD

The injection moulding process consists of four stages. The cooling phase is critical to the process and often involves direct cooling from a chiller.

Clamping

The two halves of the mould must be securely closed by the clamping unit prior to injection of the molten plastic. The clamping device provides sufficient force to hold the mould in position during injection. The clamping set up generally takes more time with larger machines that can generate more force.

Injection

Raw plastic material (generally pellets) are fed into the injection moulding machine and enter the screw assembly. Heat and pressure are applied to melt the raw plastic as it moves through the screw. The molten plastic is rapidly injected into the mould with the pressure ensuring the mould is entirely filled.

Cooling

The water-cooled mould ensures that the plastic starts to cool as soon as it contacts the interior surface of the mould. As the plastic cools, it solidifies into the shape of the desired part. Shrinkage of the part may occur during cooling. The packing of the material during the injection stage allows additional material to flow into the mould reducing visible shrinkage.

The cooling of the mould is important as the product can’t be ejected until it is sufficiently cool. Efficient cooling increases product throughput and prevents unnecessary downtime. Water is generally used as the primary cooling agent. Water is channelled through the mould to facilitate a quicker cooling time. Decreased mould temperature is generally more efficient allowing for faster manufacturing cycle times to be achieved.

Ejection

After sufficient time has elapsed, the cooled part is ejected from the mould by the ejection system located at the rear of the mould. When the mould is opened, a mechanism is used to push out the part. Once the part is ejected, the mould can be clamped shut for the next shot to be injected.

INJECTION MOULDING - COOLING OF THE HYDRAULIC SYSTEM

Injection moulding machines typically use a hydraulic pump and circuit to power the screw, press, mould and ejection componentry. Hydraulic fluid is moved by a pump and that generates significant heat during operation. Approximately 1/3 of the electrical installed power must be removed from the system to prevent machinery issues. Insufficient cooling prevents optimal operation of the press; this results in problems with the plastic maintaining its shape in the mould. Loss of batch quality and increased rejection rates alongside frequent equipment downtime originate from poor cooling capability.

The hydraulic system generally employs the use of an oil to water heat exchanger. In many cases a chiller can be used to supply cooling capacity directly to the oil to water heat exchangers, in larger installations where multiple machines are in operation.

Cooling capacity is generally supplied to the injection moulding machine through two independent water cooling circuits:

Higher temperature loop for cooling the hydraulic oil application. Chillers are often used in conjunction with free cooling and a water tower as part of a system to supply cooling capacity to multiple applications

Lower temperature loop for the plastic mould cooling. The cooling water is typically delivered between 10 – 15oC

Precise cooling is not as critical for the hydraulic oil application, temperature control for cooling the mould tends to be more critical. Precision cooling is important to deliver the correct finished quality and increase productivity. In many cases, a separate chiller will be installed for each injection moulding machine to manage heat loads.

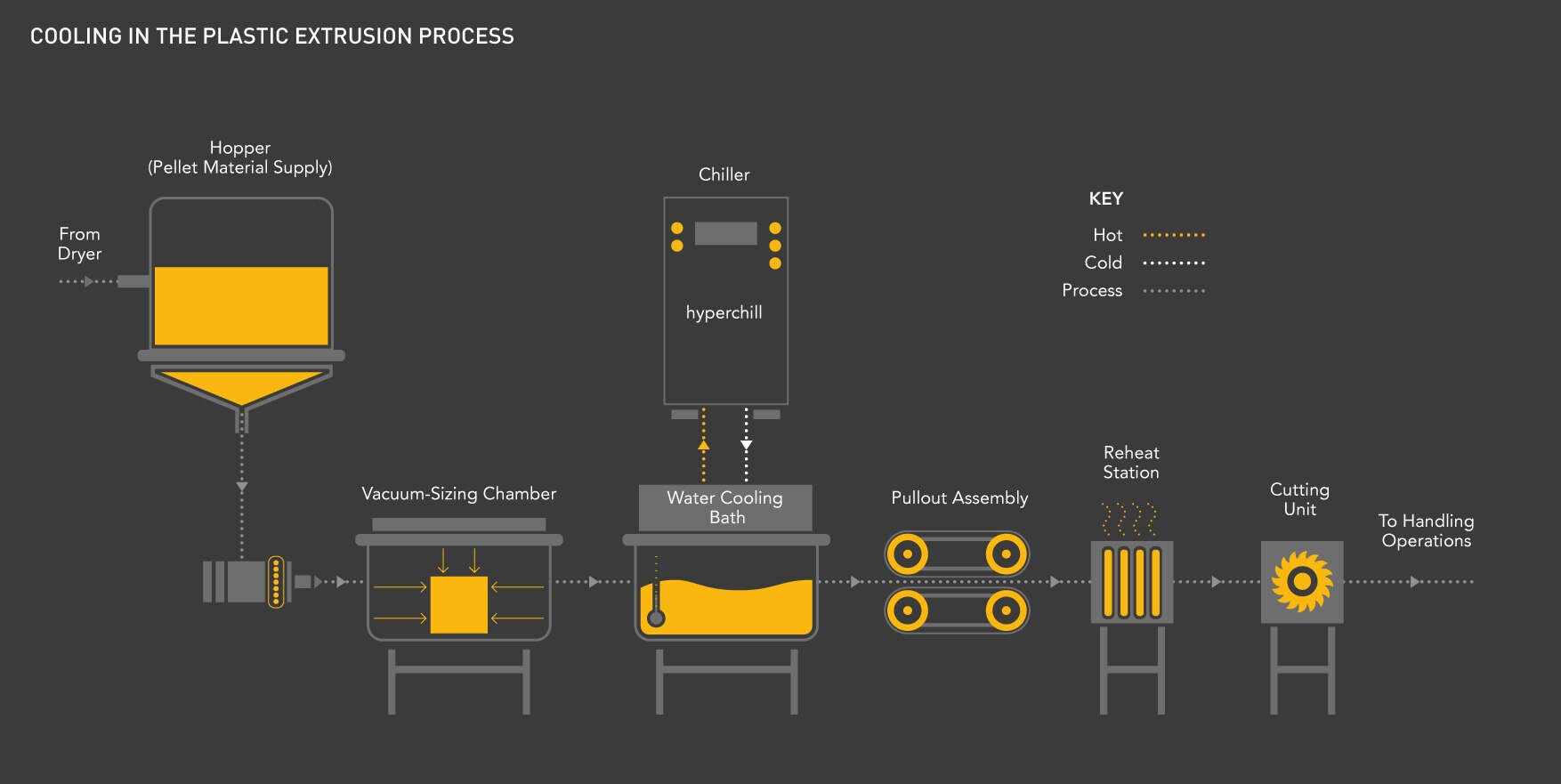

COOLING IN THE PLASTIC EXTRUSION PROCESS

The plastic extrusion method is generally used for high-volume manufacturing where raw plastic material is melted and formed into a continuous profile. Extruded plastic products include: pipe & tubing, weather stripping, window frames, plastic sheeting, adhesive tapes and wire insulation.

The following diagram depicts the stages of the plastic extrusion process:

Thermoplastic beads are gravity fed from a top mounted hopper entering the barrel of the extruder. A rotating screw forces the plastic beads forward into the barrel which is heated by resistors to the desired melt temperature. Extra heat is contributed by the intense pressure and friction taking place inside the barrel.

At the front of the barrel, the molten plastic leaves the screw and travels through a screen pack to remove any contaminants in the melt. After passing through the breaker plate, the molten plastic enters the die that is responsible for forming the final product shape.

The product must be cooled as it leaves the die; this is generally achieved by drawing the plastic through a large water bath. In tube or pipe extrusion lines, the product is often cooled in a sealed water bath with a controlled vacuum to prevent the newly formed molten product from collapsing. Once the product has been cooled it can be spooled or cut into lengths for later use.

For products such as plastic sheet or film, the cooling is achieved by pulling through a set of cooling rolls. In sheet extrusion, these rolls not only deliver the necessary cooling but also determine sheet thickness and surface texture.

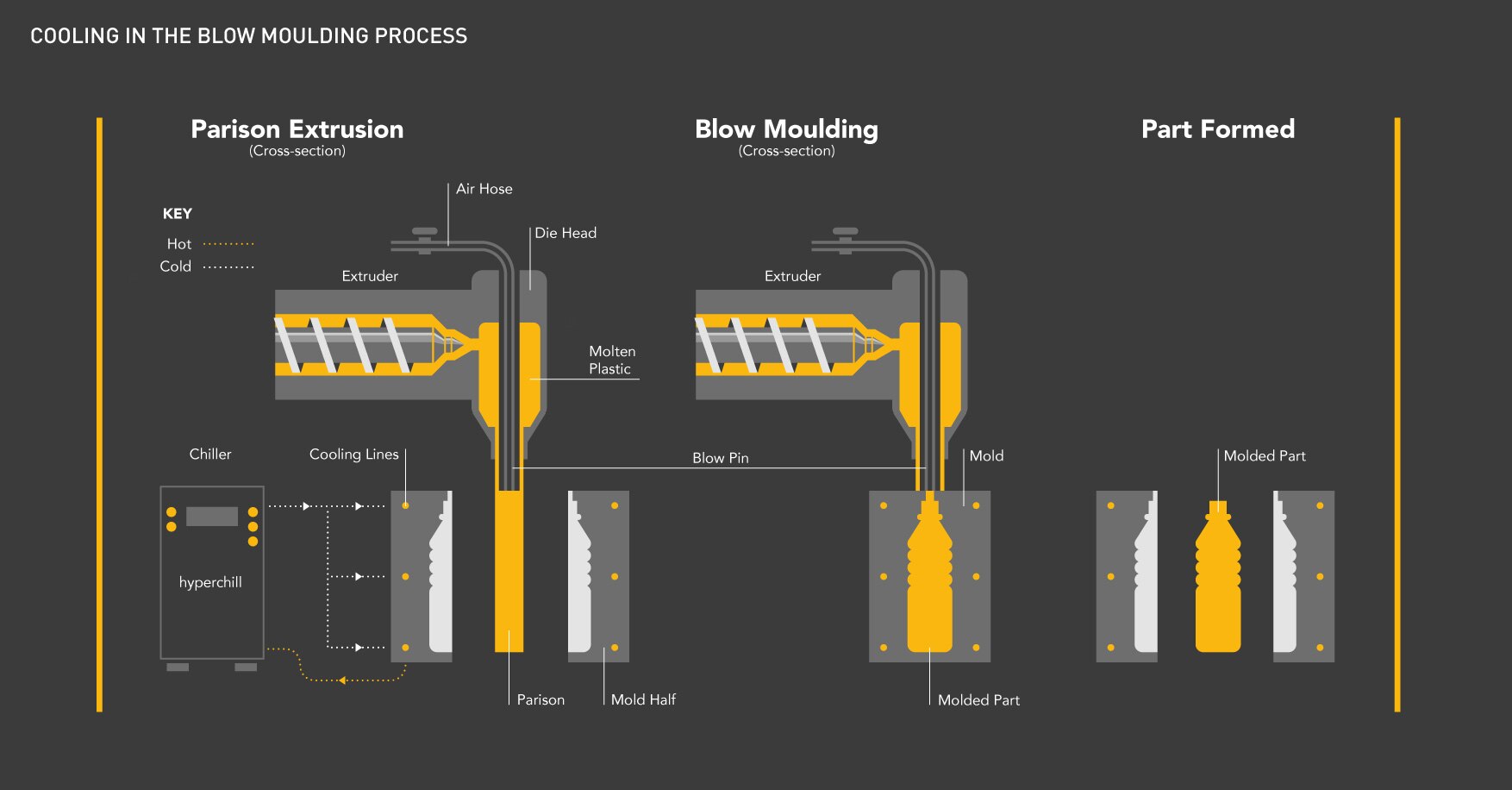

COOLING IN THE EXTRUSION BLOW MOULDING PROCESS

Extrusion Blow Moulding is commonly used to produce plastic beverage bottles. Around 508 billion plastic bottles were manufactured in 2018 with growth to 583 billion by 2021. Almost all plastic bottles were manufactured using the blow moulding technique. Most of the plastic bottles destined for the beverage market are manufactured from polyethylene terephthalate (PET).

The following diagram depicts the key steps in the extrusion blow moulding process:

In the above process plastic is melted and an injection extrusion process is used to create a small hollow tube called a parison (or pre-form).

The parison is captured and enclosed within a metal mould that contains cooling channels. Clean dry compressed air is blown into the parison inflating it to form the shape of the hollow bottle, container.

or part. The plastic must be cooled before it can be ejected from the mould. A typical mould can be seen in the picture below:

A critical stage in the extrusion blow moulding process is the cooling phase. The final product is technically “frozen” inside the mould cavities using cool water flowing through the cooling channels.

Because blow moulding typically uses an injection moulding technique to form the parison, the heat load from the hydraulic circuit powering the press must be removed.

More precise cooling capacity must be delivered to the mould responsible for cooling the finished product prior to ejection. Typical cooling requirements for the mould are as follows:

- Typical water temperature range between 10 – 15oC

- Temperature Delta approximately 2oC

- Water pressure maintained around 5 bar

When calculating the cooling capacity required for the blow mould, the target mould temperature in and quantity of plastic that will be blown per hour must be obtained. The Kcal/hr of heat load that needs to be removed from the mould can then be calculated. For additional sizing information please contact your local Parker specialist.

Why Parker Chillers

Parker Hyperchill and Hyperchill Plus chillers offer an ideal solution for plastic industry, providing a one-package solution to meet the different needs of plastic production processes thanks to:

- All-in one solution including internal water tank, pump and bypass.

- High pressure pumps, designed to overcome water pressure drops of the mould cooling channels.

- Generous size water tank and oversized condenser and evaporator, giving the chiller higher flexibility and ability to operate at high temperature gradients, therefore ensuring reliable and continuous operation of the customer machine.