A consequence of the modern machines running at higher speeds is that they use more energy.

This generally results in the liberation of more heat. In most print applications the excess heat is a problem for the following reasons:

- At higher temperature the printing ink viscosity decreases. Over emulsification of the ink occurs leading to smearing and smudging of the print

- Increased quantities of low viscosity ink may be required to achieve the print. The use of larger ink volumes results in increased print costs

- High heat levels increase the wear on the printing system resulting in more frequent maintenance work

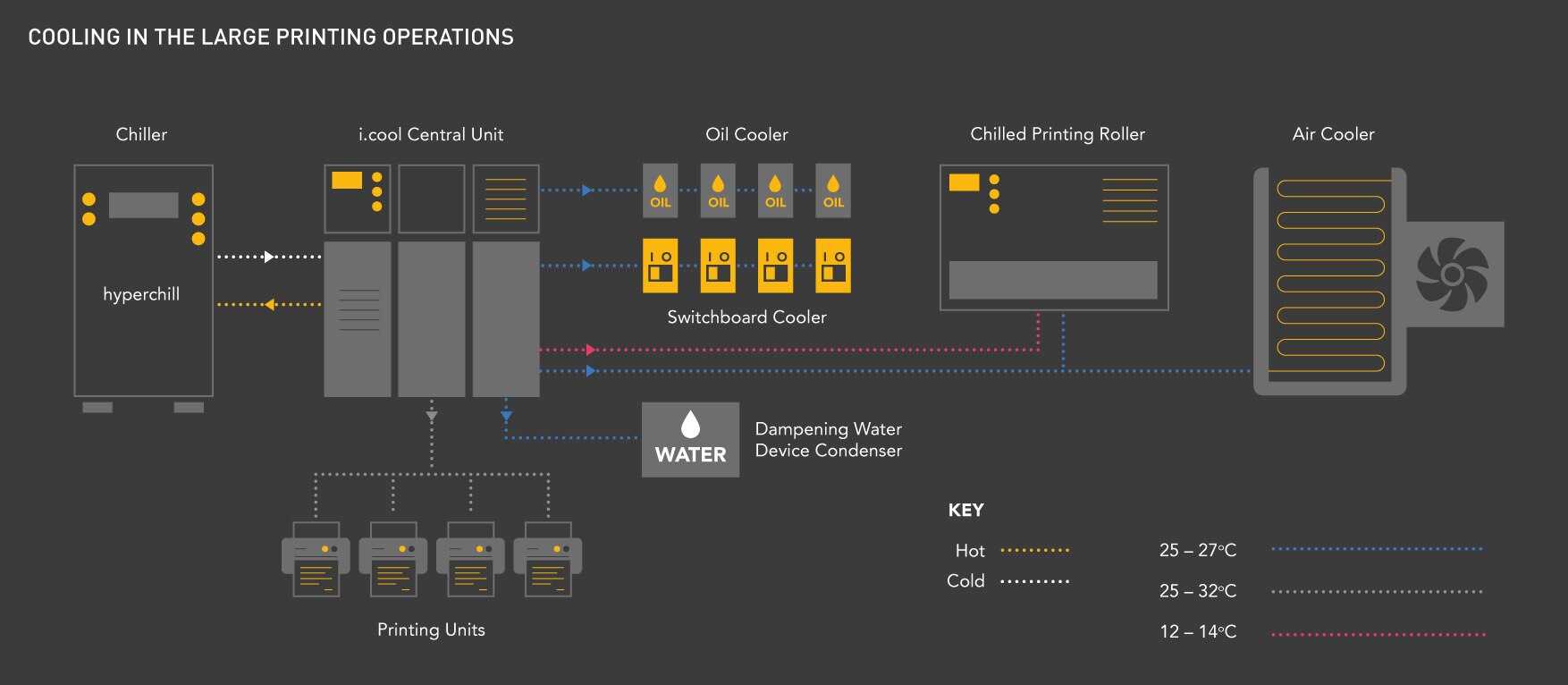

Chillers play an essential role in printing applications. They are vital in providing the machinery with temperature stability, which is in-turn, critical to ensuring the quality and speed of production is maintained.

Most machine manufacturers circulate chilled water through the critical components to reject the unwanted heat and provide stable working temperatures.

The heat load is generally removed by circulating chiller water through the print roller or through the UV curing lamps.

Direct Cooling of Rollers

Chilled rollers provide cooling directly to the product to maintain consistency of throughput. The chilled water passes through rotary unions at each end of the roller.

Cooling of UV & LED Lamps

UV and LED Lamp Systems are used to create ultra violet light that can be directed onto the printing surface. The UV light reacts with the wet ink resulting in rapid curing and drying. The UV curing method is common in modern and large print systems as the printing throughput can be significantly increased. Chilled water is typically passed through a heat-sink attached to the bulb mounts and maintains a stable operating temperature.