Precision water chillers are routinely found in hospital and laboratory applications. Important applications for precision water chillers include the heat load management in Magnetic Resonance Imaging (MRI) and Computed Tomography (CT) scanners. The main manufactures of MRI & CT scanners include: Siemens, Toshiba, Philips & GE.

Water chillers are also used in the laboratory to control temperature in a variety of applications. These would include: rotary evaporation, reaction vessel jacketing, diffusion pumps, laser systems, electron microscopes & linear accelerators.

Magnetic Resonance Imaging

What is an MRI Scanner?

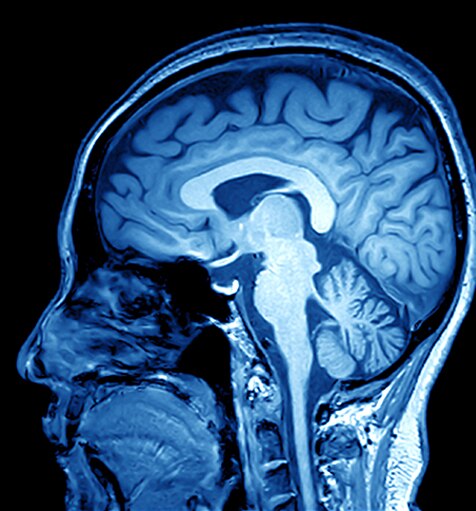

MRI (Magnetic Resonance Imaging) is a non-invasive scanning technology that produces cross sectional images of the body. It is used in a range of medical fields including: musculoskeletal, gastrointestinal, oncology, cardiovascular and neuroimaging. MRI scanning can differentiate soft tissue structures in any plane making it an invaluable diagnostic tool.

MRI scanners generate a strong magnetic field that is used in conjunction with radiofrequency currents to stimulate specific molecules in the body.

The behaviour of the molecules can be used to generate a three-dimensional image of body tissues. Example MRI images are shown below:

Basic MRI Operation & Cooling Requirements

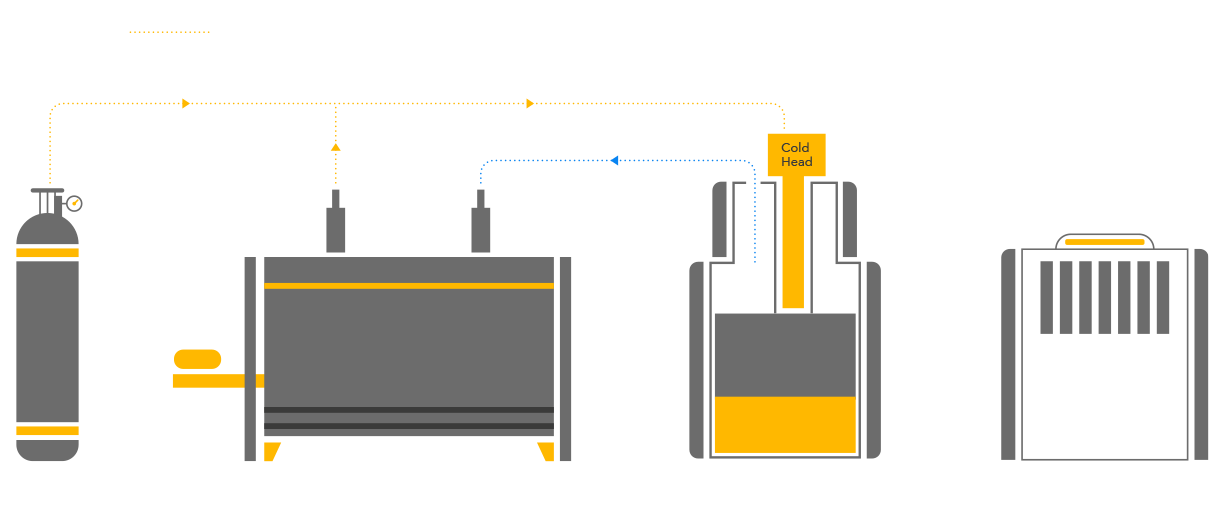

All MRI scanners contain superconductive magnetic coils. These coils must be cooled to approximately -296oC to promote superconducting properties in the metal alloys. The low cooling temperature is achieved by circulating liquid helium around the magnetic coils.

An average sized MRI scanner contains approximately 1,700L of Helium. A mechanical device called the cold head is used to minimise the loss of helium. The device re-condenses gaseous helium back to a liquid state after contact with the magnets.

An efficient cold head minimises the loss of gaseous helium over time and maintains the effective operation of the magnets.

A diagram of the cold head circuit can be seen below:

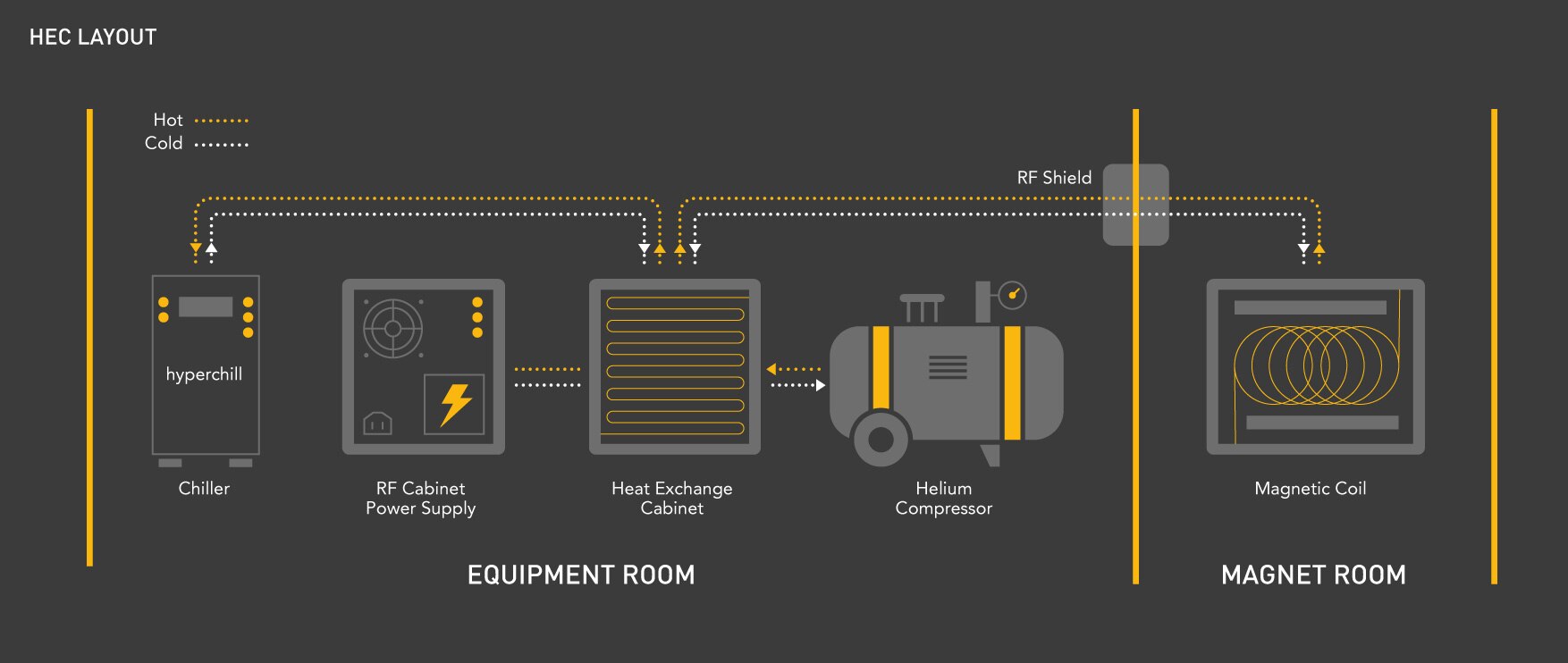

In addition to controlling the ambient temperature around the MRI scanner, heat must be removed from several processes during machine operation. These include the following:

- A helium compressor is used in conjunction with the cold head to compress the gaseous helium prior to recirculation to the MRI magnet. The heat load from the compressor motor must be removed to maintain efficiency of the helium circuit.

- RF cabinet & amplifiers generate significant electrical heat. This heat must be removed from the electronics system within the scanner.

- Direct cooling around the magnetic coils is employed to remove ambient heat and improve the magnet cooling efficiency (compliments the HVAC control of the room temperature).

Chillers can be integrated into the MRI system to provide cooling capacity in several ways. In most instances, the chiller is used in conjunction with a Heat Exchange Cabinet (HEC) located in the equipment room (kept separate to the magnet room). The HEC utilises heat exchangers that can be connected to the water supply from the chiller, several applications are then serviced indirectly by the chiller.

An example layout of the HEC is given below:

COMPUTERIZED TOMOGRAPHY SCANNING

What is a Computerised Tomography scanner?

Computerised Tomography (also referred to as Computerised Axial Tomography, CAT) is a scanning technique that uses X-ray to produce cross sectional images of the body. The images provide more detail of body structures when compared to a standard X-ray. Hospitals have a high demand for CT scans due to the range of diseases and conditions that can be diagnosed.

The CT scanner uses motorised X-ray tubes that move around the patient. The X-ray that pass through the patient are picked up by detectors that send data to a computer for processing.

Why are Precision Water Chillers Required

CT scanners generates a significant heat load during operation. The electrical componentry and X-ray tubes in modern scanners consume >95 KW of power. Excess heat in the scanner gantry must be removed on scan completion to allow for the next scan to be initiated.

The X-Ray tubes can take between 20 – 30 minutes to cool sufficiently without cooling. A water chiller significantly reduces the cooling time and protects the scanner from overheating. Patient throughput, enhanced care & hospital efficiency are greatly improved. Unnecessary maintenance related to process overheating is also reduced helping to drive down overall operation costs.

Why Parker Chillers

Hyperchill and Hyperchill Plus chillers have a proven track record of performance with all the major manufacturers of CT scanner systems.

The Parker system offers the following key benefits:

- Non-ferrous hydraulic circuit for increased reliability and reduced maintenance costs.

- Large water tank capacity increasing both process cooling stability and compressor lifespan.

- Reduced maintenance cost and hence cost of ownership.

- Built-in maintenance indicators and fault switches to safeguard the capital equipment.

- Configurable with a 5 bar pump to meet system pressure requirements.