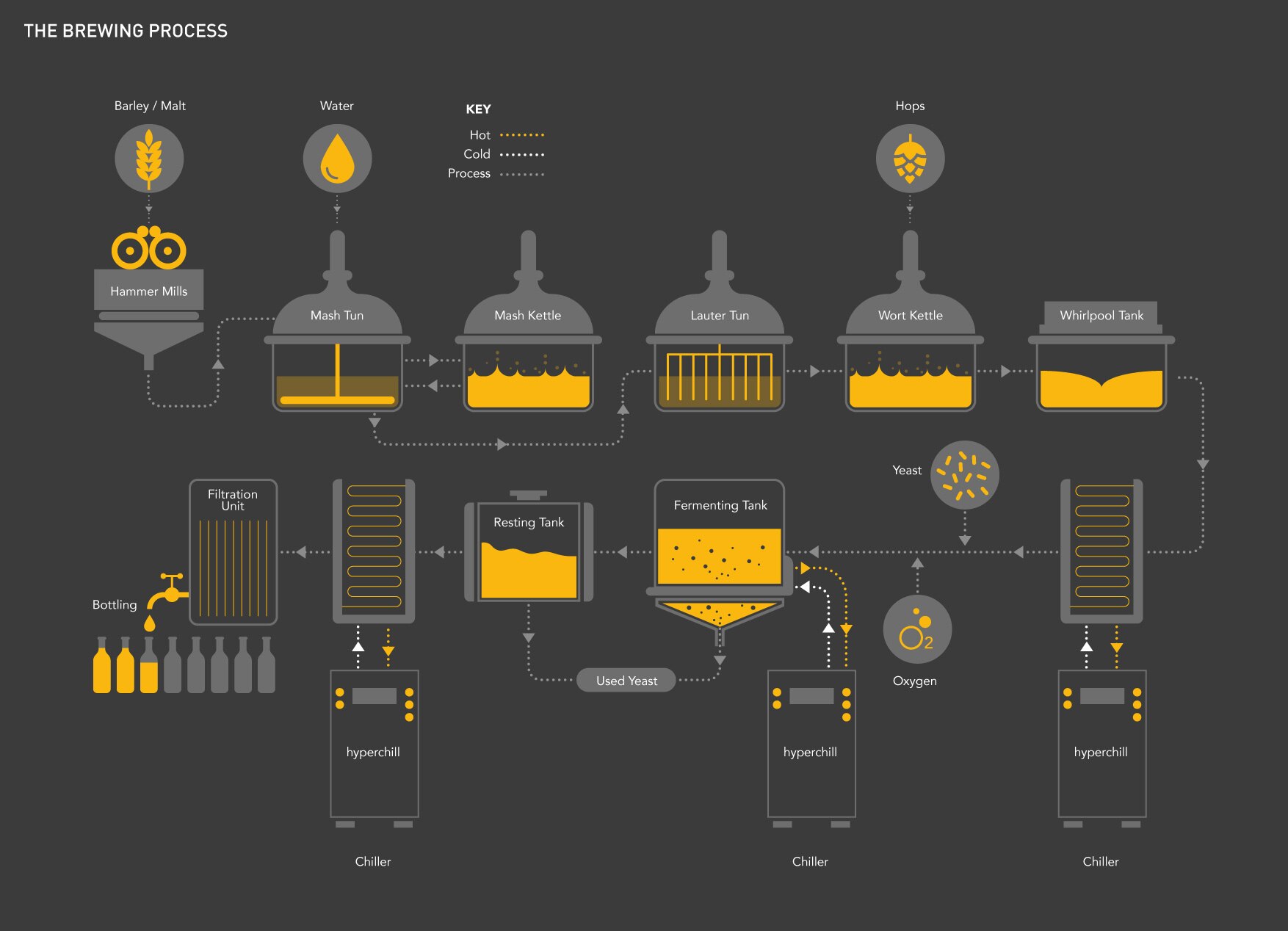

During the initial stages of brewing, grain kernels are milled to form grist. The grist is transferred to the mash tun and heated water is added. During mash conversion, natural enzymes in the grist break down the malt starch into fermentable sugars. The mash is then pumped into the lauter tun where a sweet liquor (wort) is separated from the grist.

The wort is transferred to a kettle and heated to a controlled boil temperature of approximately 60°C before hops are introduced. After the boiling phase, residual malt and hop particles are removed.

Whilst the wort is still hot it is rapidly cooled for the following reasons:

- The wort is susceptible to oxidative damage if left to cool slowly. Rapid cooling minimises oxidative damage minimising unwanted flavours in the product.

- Trace quantities of dimethyl sulphide (DMS) evolve from the wort during the heating stage. DMS has a low boiling point and evaporates out of the

hot wort. As the wort is cooled, DMS is still produced, slow cooling allows DMS to accumulate due to limited ‘boil off’ in the brew. High DMS

levels in beer & lager can add ‘off-flavours’ and taint the brew. Rapid cooling of the wort to ~ 25oC minimises oxidation and DMS levels

improving the flavour profile of the final beverage.

- Rapid cooling achieves a ‘cold break’. Proteins are thermally shocked and precipitated from the wort. A lack of rapid chilling can result in a ‘chill

haze’ in the finished product. Residual proteins can precipitate as the product is cooled before consumption. This is often considered undesirable

especially if the product should be clear.

How is wort cooling achieved?

Most breweries pass the wort through a single or double stage plate heat exchanger to achieve cooling. The application is demanding; a significant heat load must be removed quickly form the process. A glycol water mix on the water circuit is common to provide enhanced cooling capacity. A double walled food grade heat exchanger is generally selected to prevent contamination issues between the wort and cooling fluid.

When sizing a chiller for wort cooling the following must be considered:

- Overall volume of wort to be cooled (often quoted in BBL /barrel volumes).

- Desired ‘knock out’ time (cooling time required to optimise the process).

- Initial wort temperature and the desired final wort temperature.

- Will the chiller also be providing cooling capacity for other brewing processes?

For further sizing details please consult with your local Parker specialist.