The 4 Major Benefits of Dehumidifying Biogas

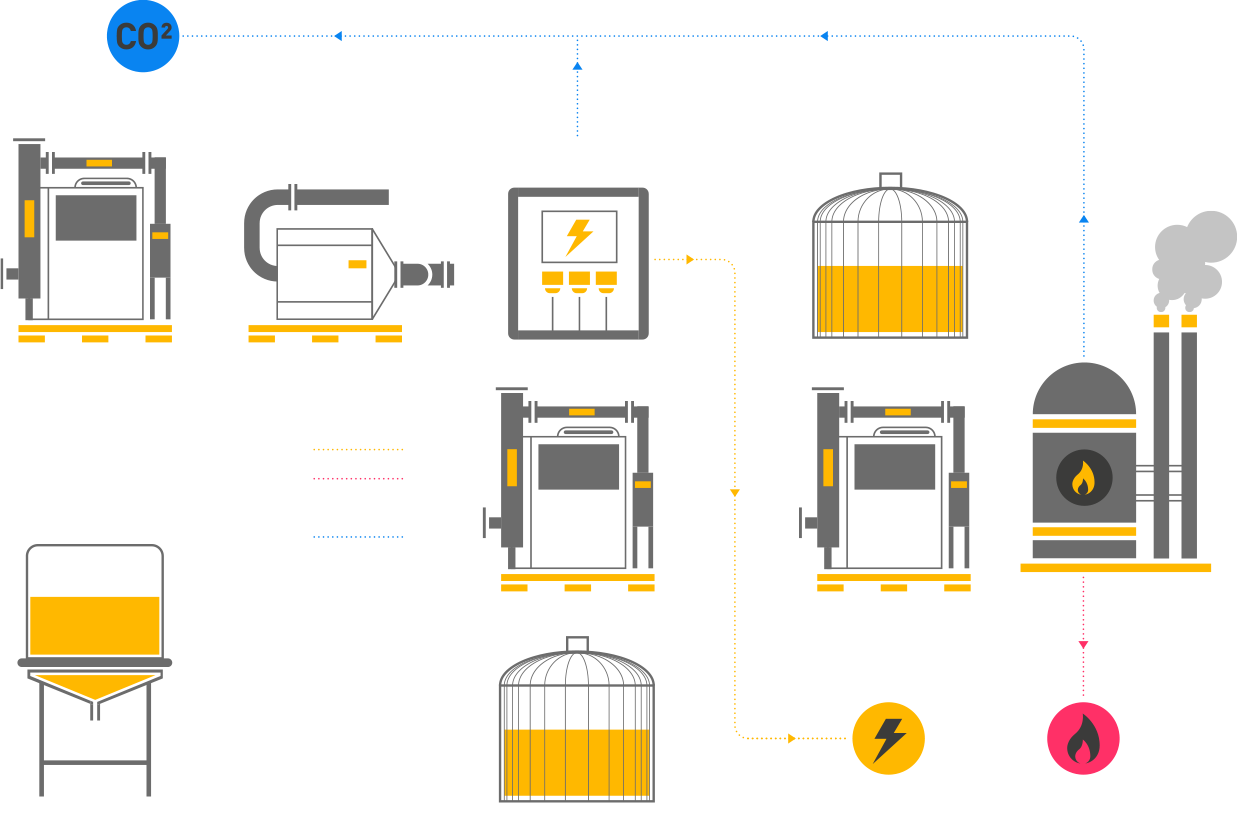

There are four major benefits of dehumidifying biogas. It will increase the energy content of gas, prevent the corrosion of pipework and system components, partially removes or reduces concentrations of specific gases, and complies with instructions from major gas engine suppliers.

1. Increases Energy Content of Gas

Raw biogas usually has a very high-water vapor content (between 30 and 100 g water per m3 gas), which equates to between 4 and 8 percent of the total gas composition and reduces the calorific value of the gas. Drying biogas to a dew point of 5oC reduces the moisture content to 1 percent, thus increasing the methane content by around 5 percent. This, in turn, increases the calorific value of the gas.

2. Prevents Corrosion of Pipework and System Components

When ambient temperature drops, the gas cools, causing water vapor to condense in the pipeline. Condensate can combine with CO2, hydrogen sulfide (H2S), etc. to form an acidic compound that causes the accelerated corrosion of machines, gas scrubbers, pipelines, buffer vessels, sensors and instruments. The combination of H2S and water produces sulphuric acid and/or ionic hydrogen, and the combination of CO2 and water produces carbonic acid. The resulting acidic condensate is highly corrosive and will cause a rapid drop in the alkalinity of the engine oil. Drying the gas to a low dew point ensures that water vapor does not condense, thereby preventing the production of these corrosive acids.

3. Partially Removes H2S, Ammonia, Siloxanes and Other Water-Soluble Gases

With efficient dehumidification, it is possible not only to remove the water vapor, but also to reduce the concentration of components, such as H2S, siloxanes, ammonia and halogen compounds, each of which dissolves in the condensed water. The partial or complete removal of these contaminants improves the efficiency of the whole plant and greatly reduces maintenance costs and plant downtime.

4. Complies with Technical Instruction of Major Gas Engine Suppliers

Unlike petrol and diesel fuels, gaseous fuels generally do not have to comply with strict quality specifications. For this reason, the manufacturers of cogeneration engines issue technical instructions to ensure the fuel gas is of sufficient quality to prevent any negative effects on engine performance and service life.

In terms of water content, all major engine manufacturers are clear in stating that water condensate in the fuel gas pipes or engine is NOT acceptable.

Installing a cooling system to dry the gas to a low dew point will ensure that water vapor does not condense in the gas pipe, which helps meet the technical instructions of the major gas engine suppliers.