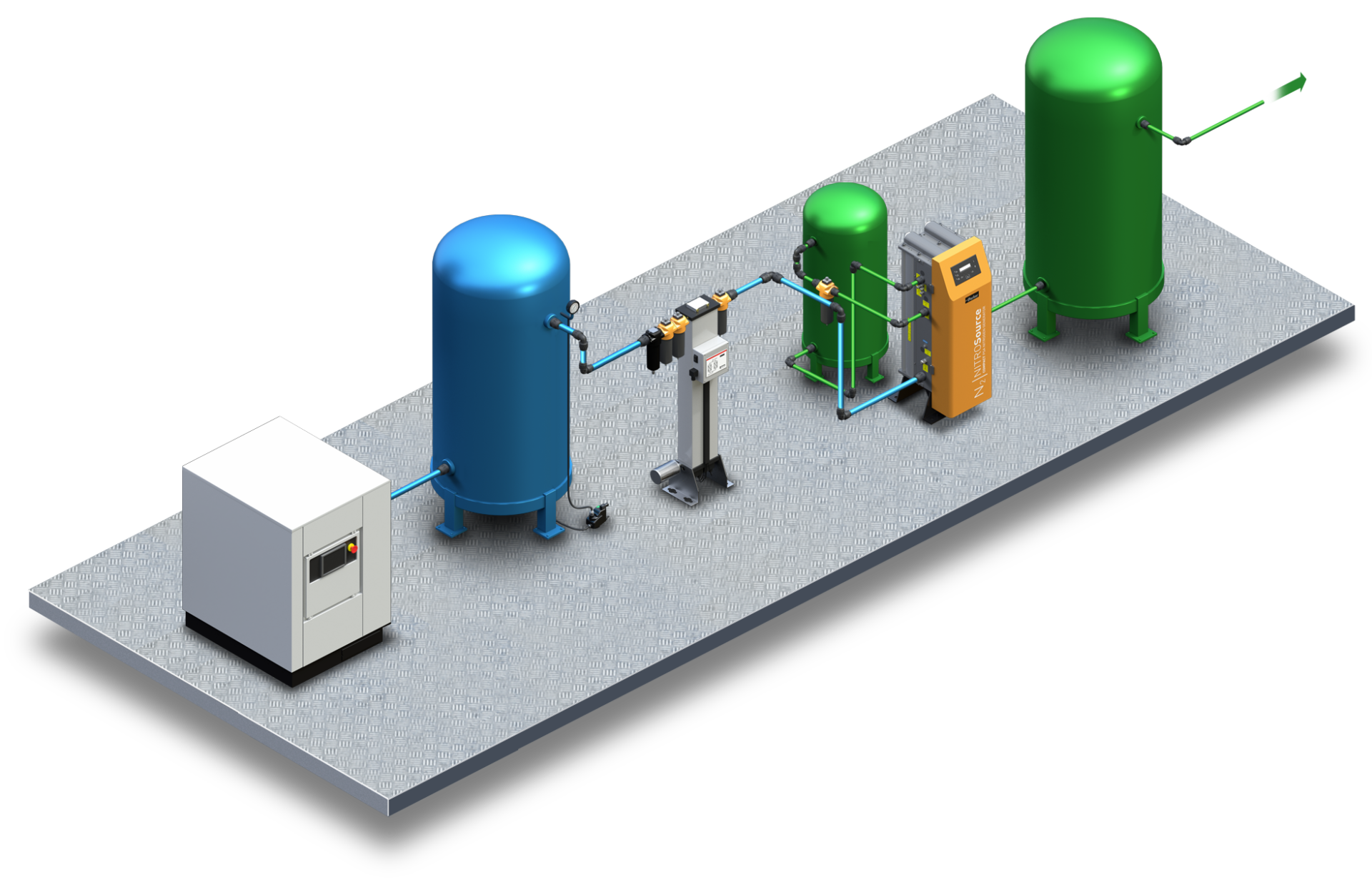

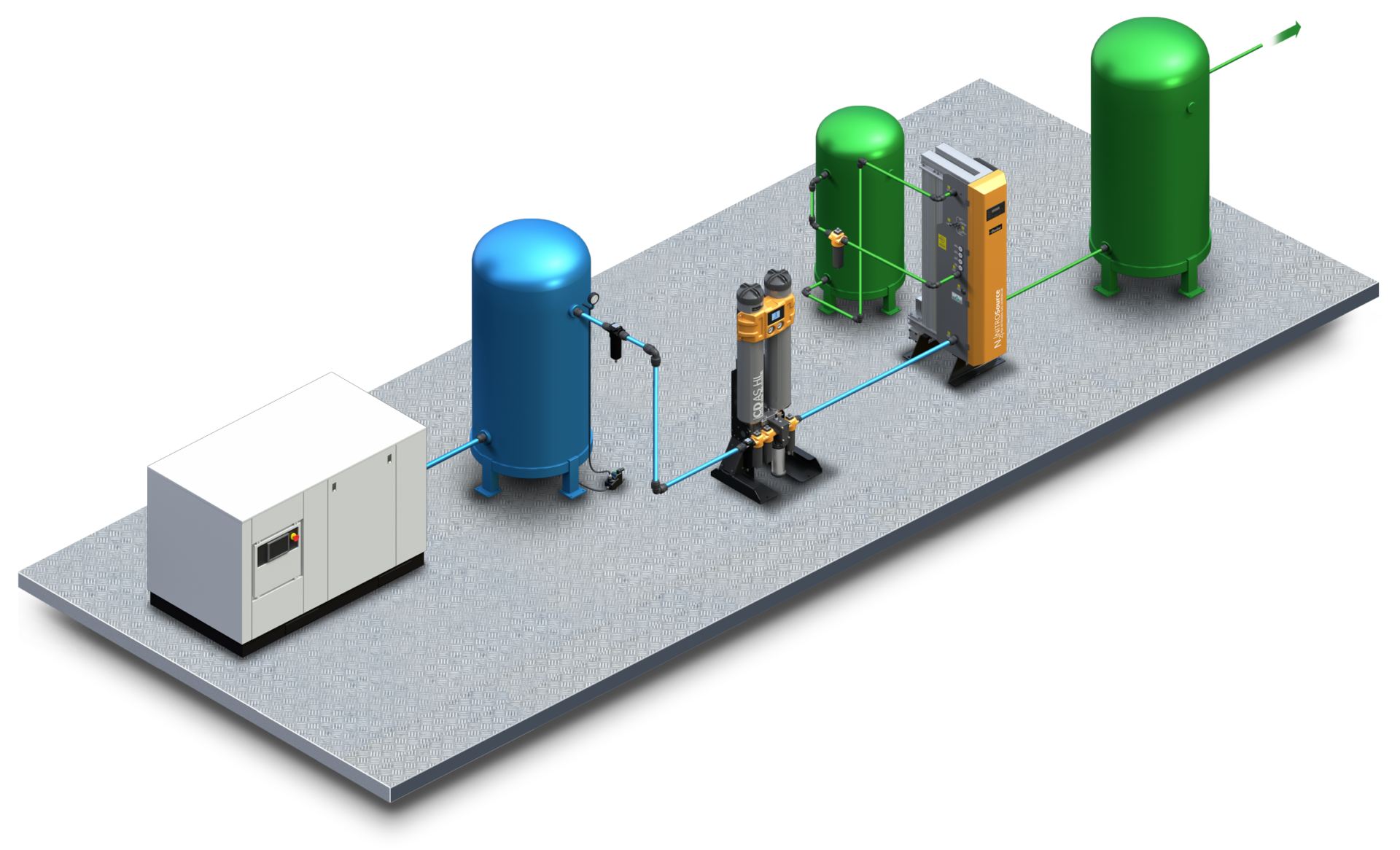

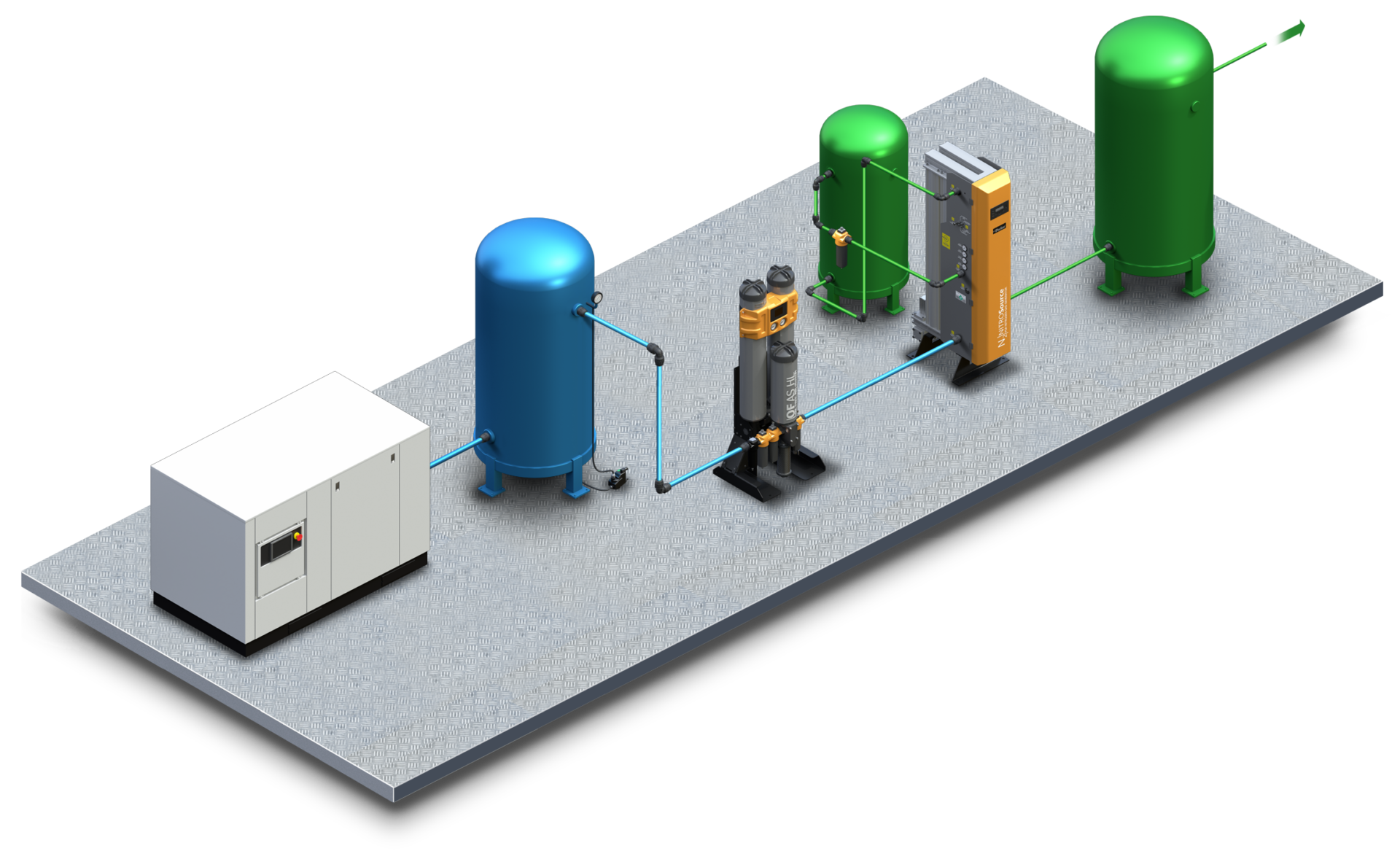

SYSTEM DESIGN

NITROSource PSA and NITROSource Compact provide a very safe, cost effective and convenient source of gaseous nitrogen.

When considering system design, and installation, there are a few points to consider to ensure a trouble free operation and long service life.

Please refer to the appropriate user manual for full installation instructions.

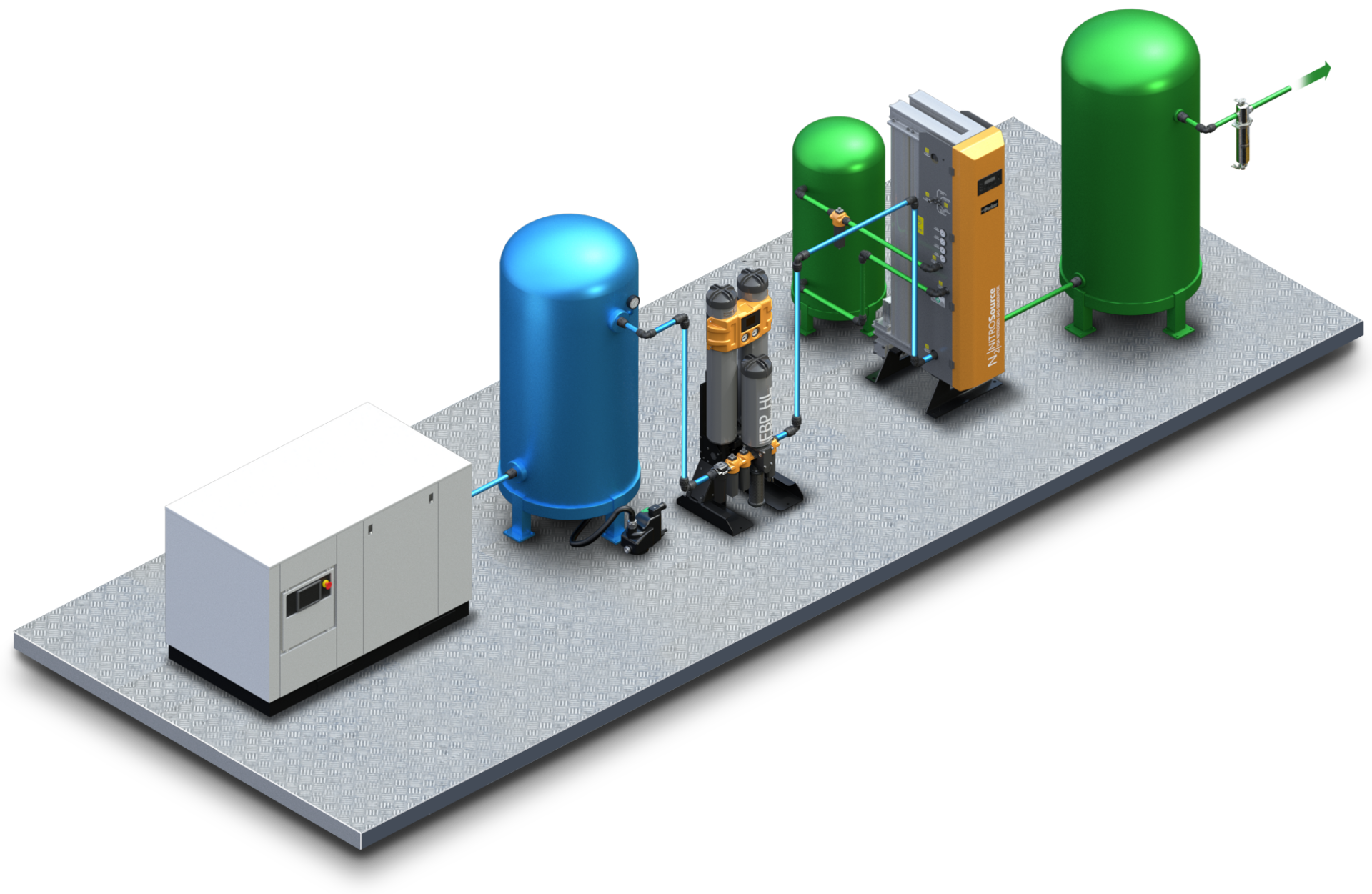

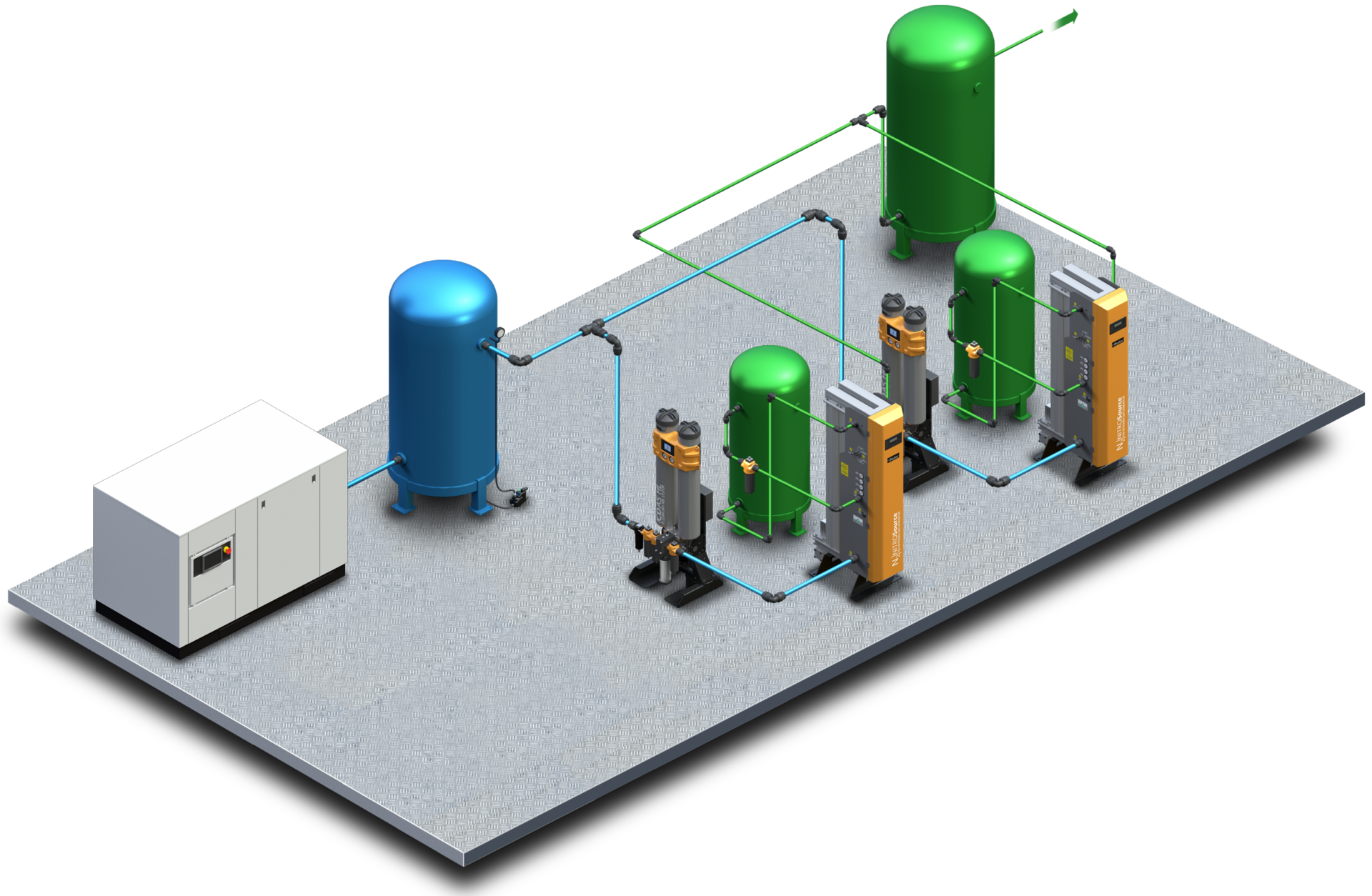

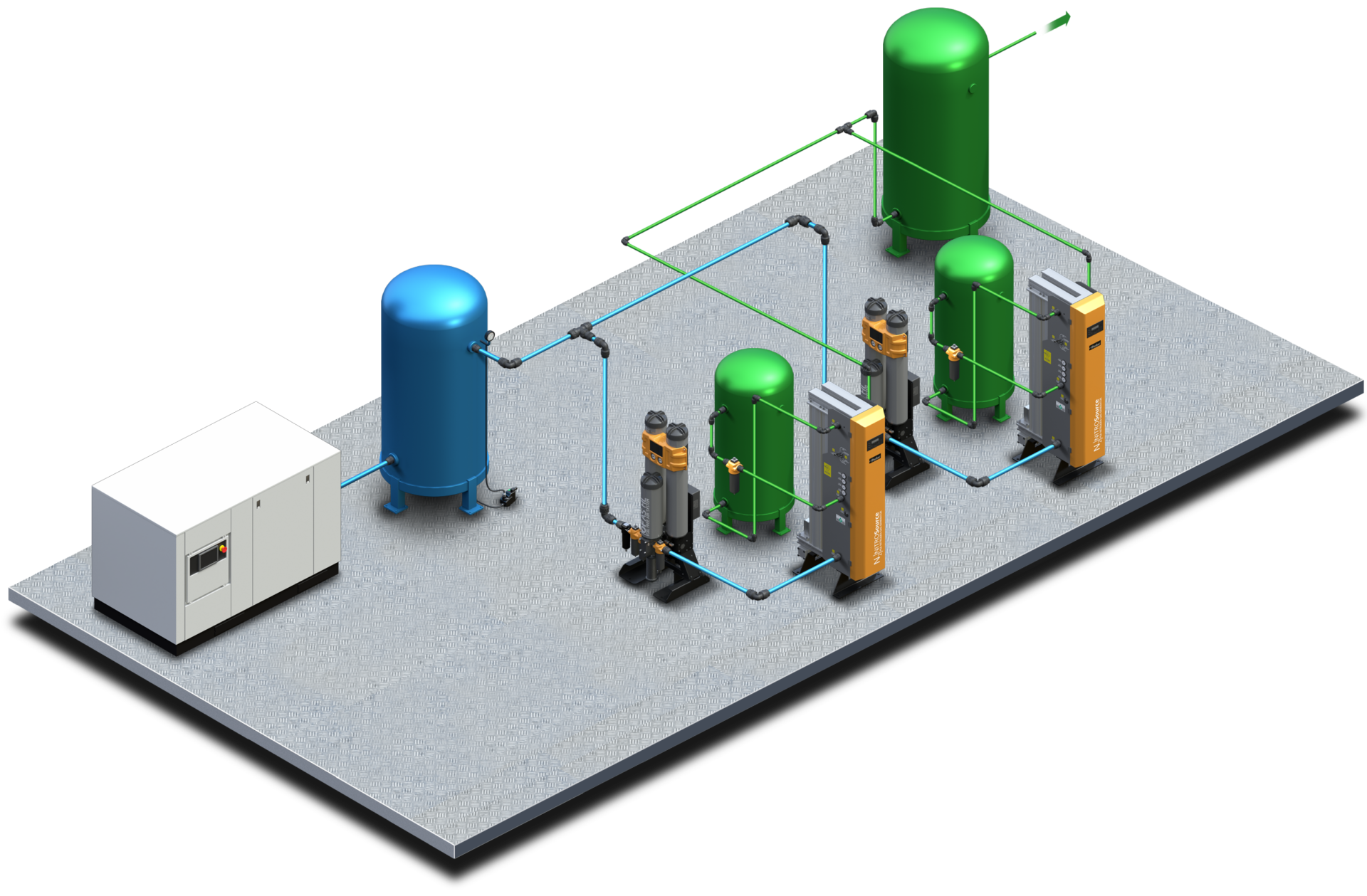

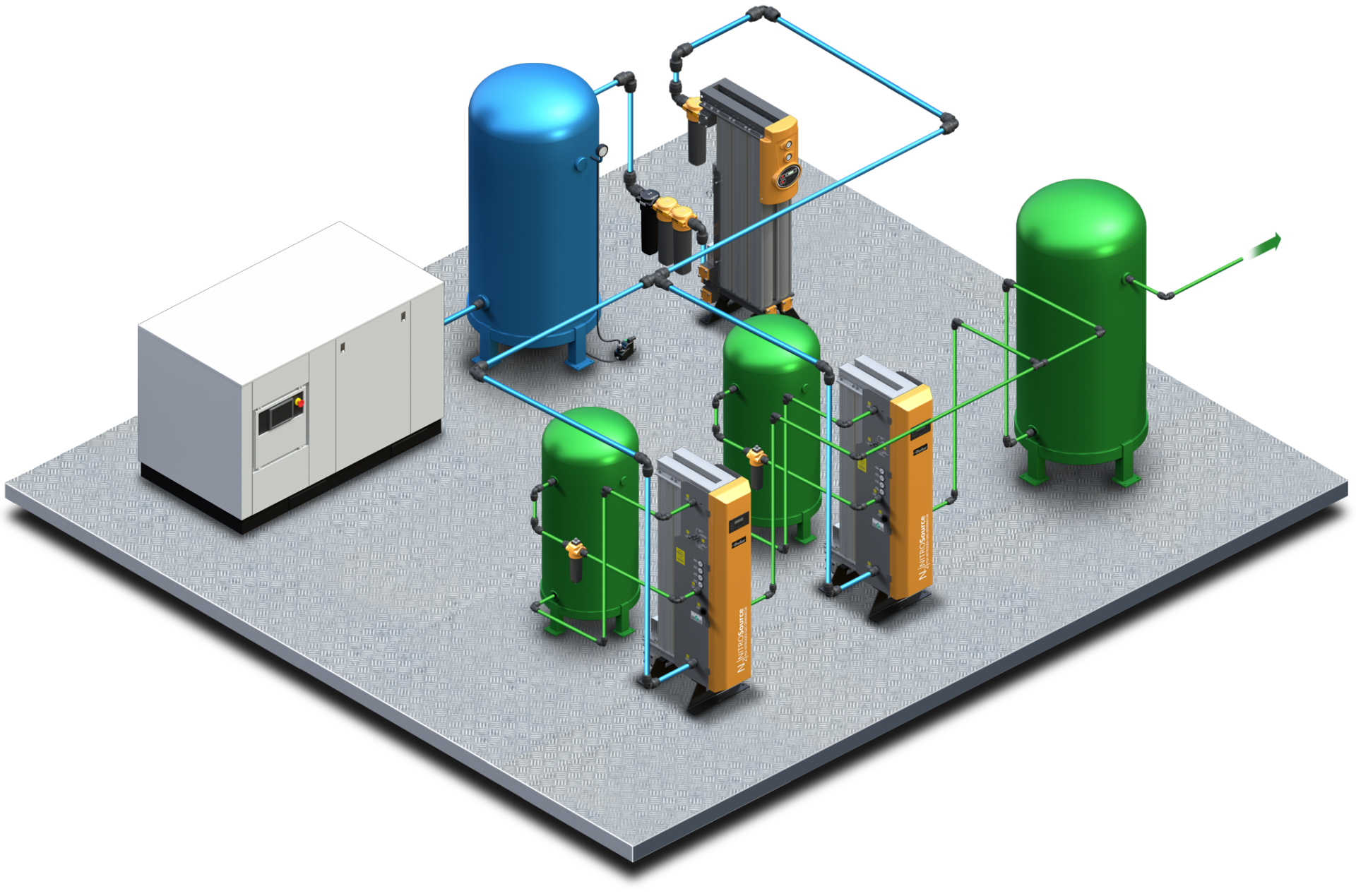

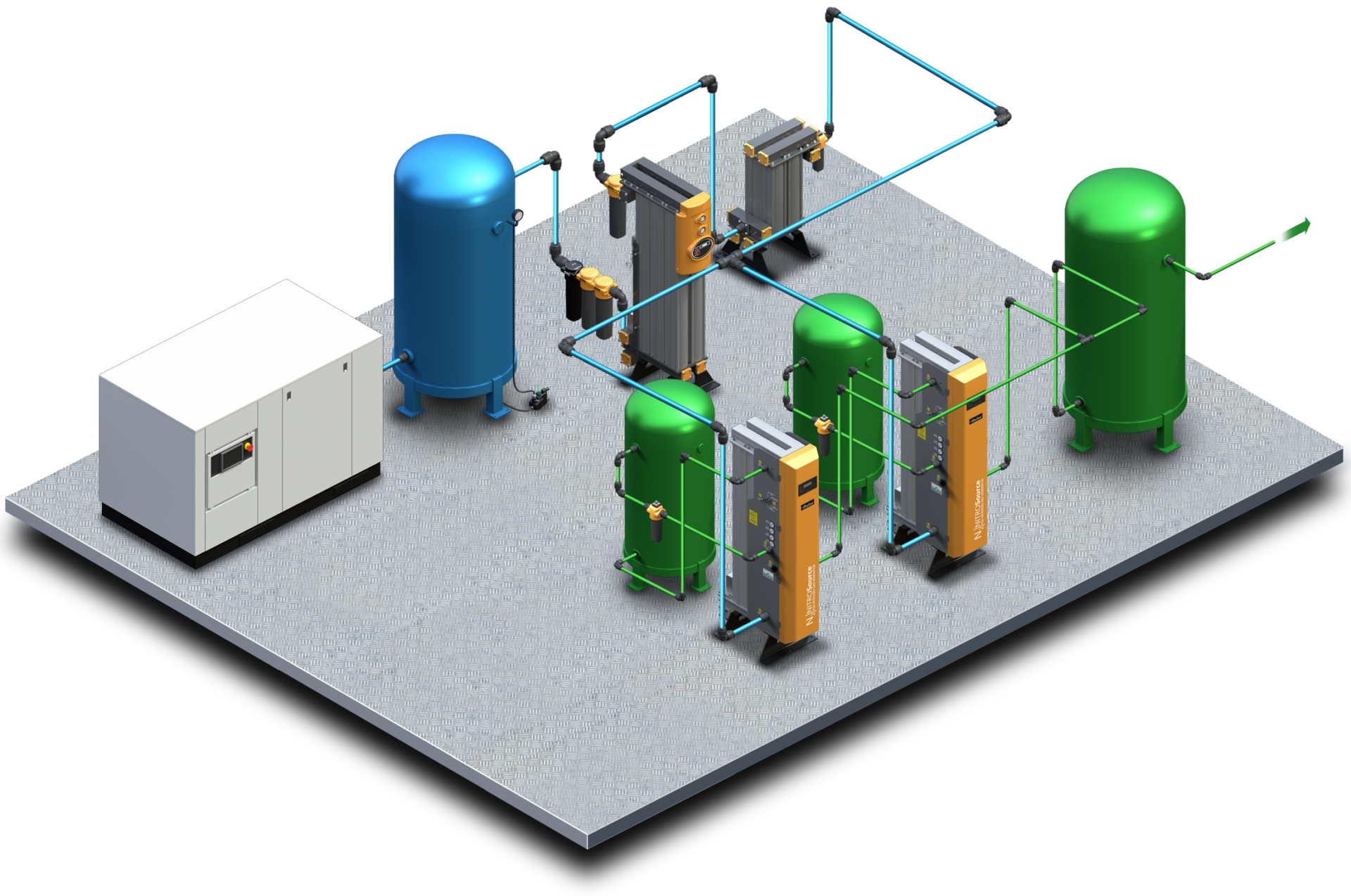

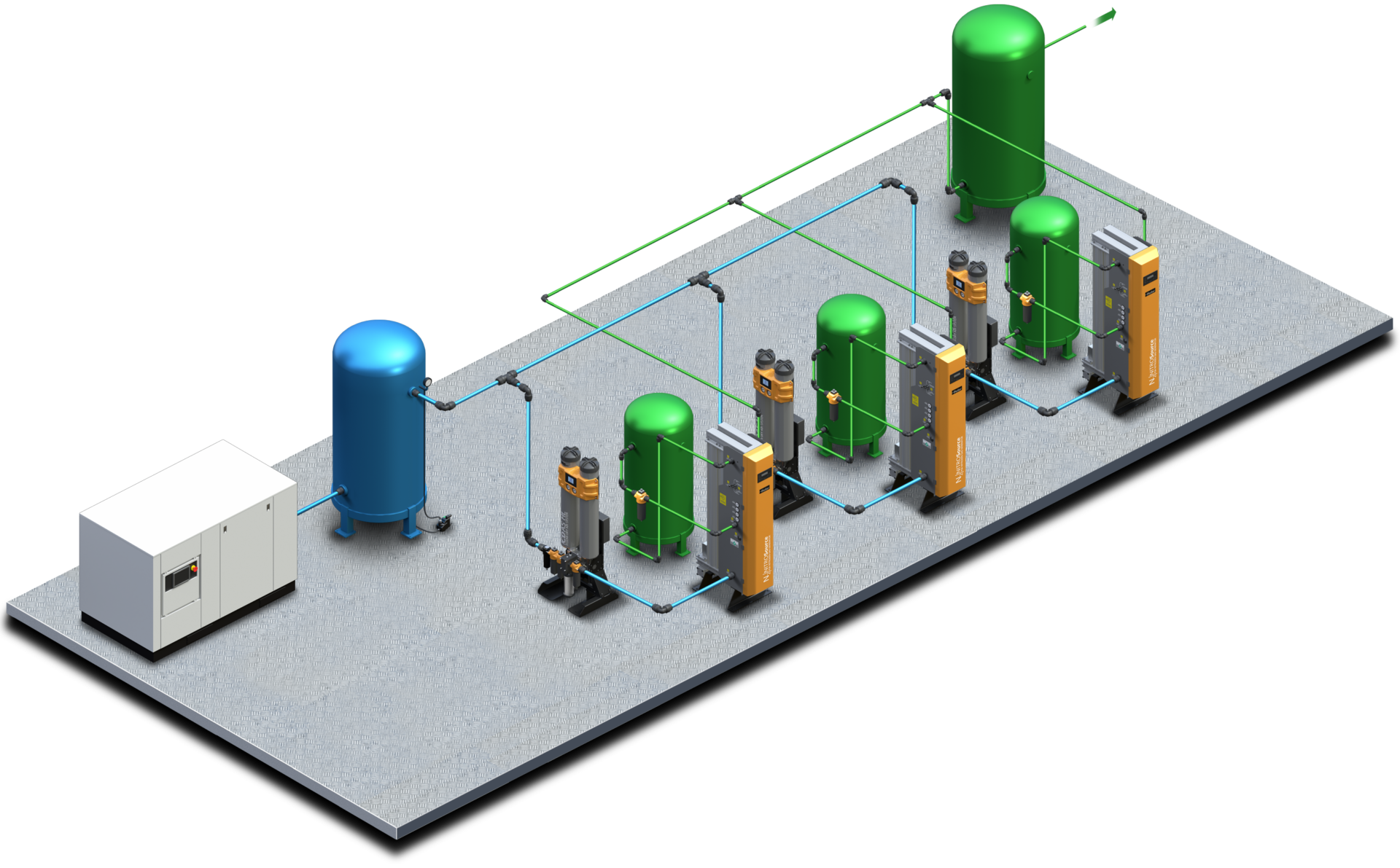

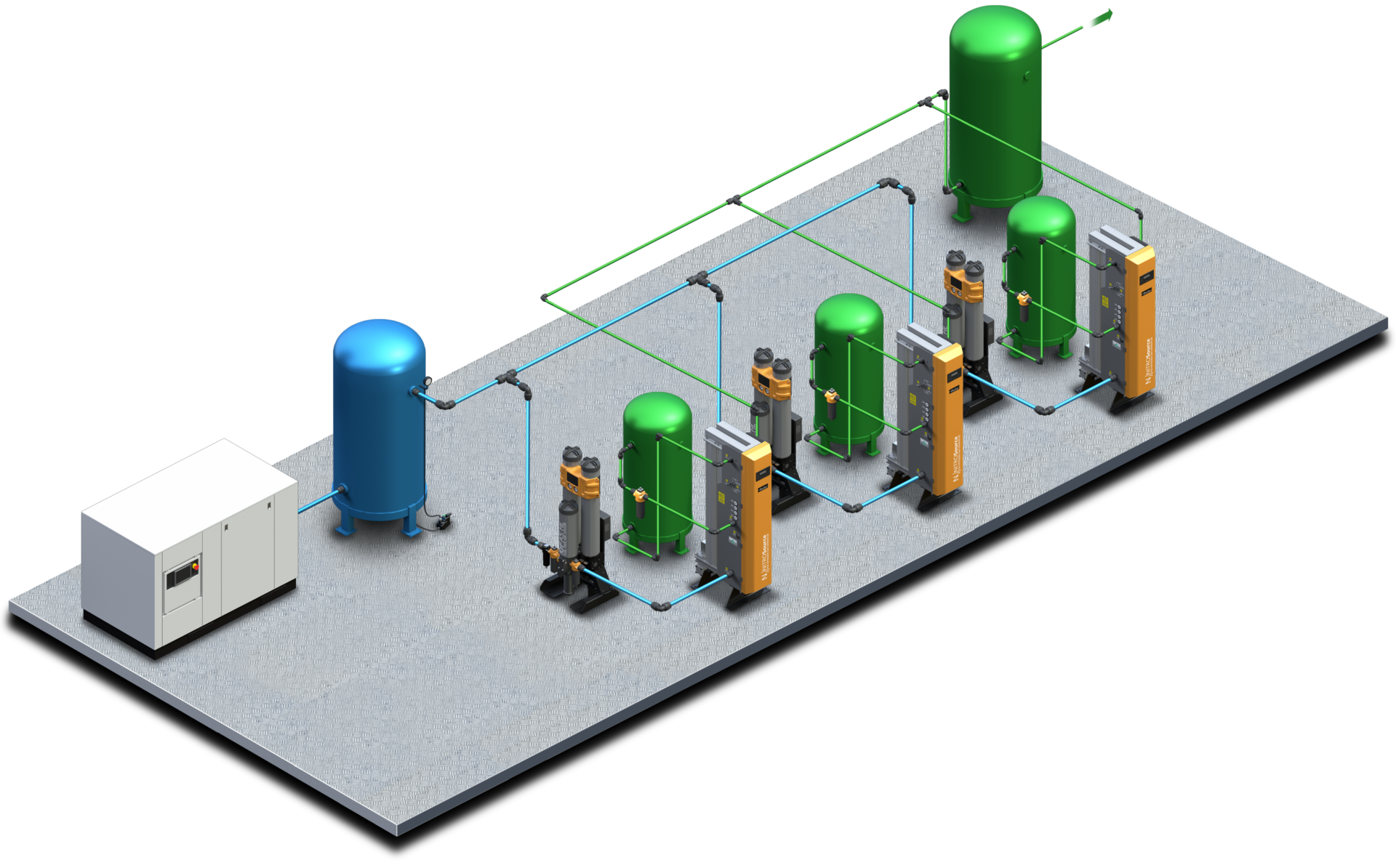

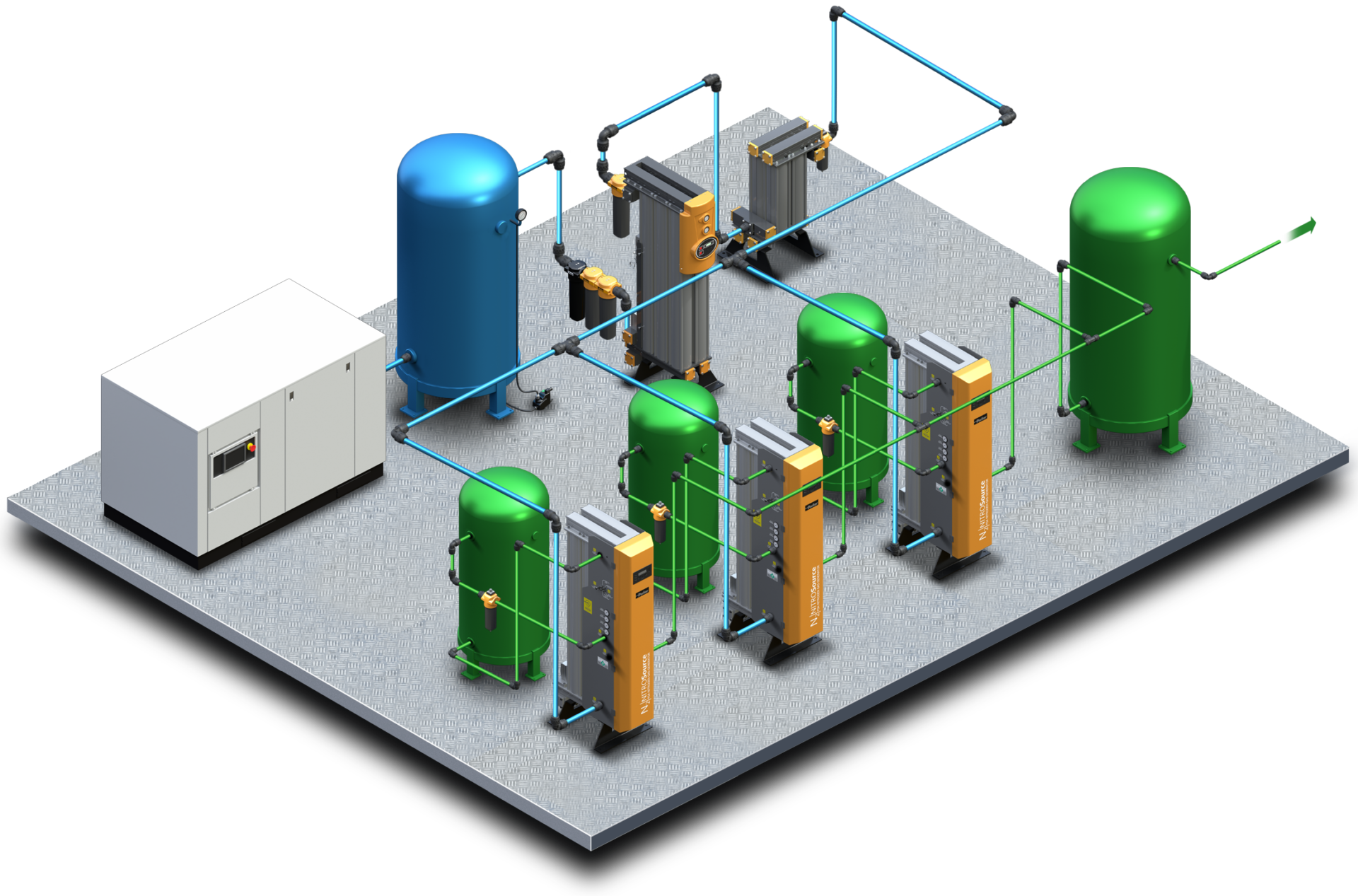

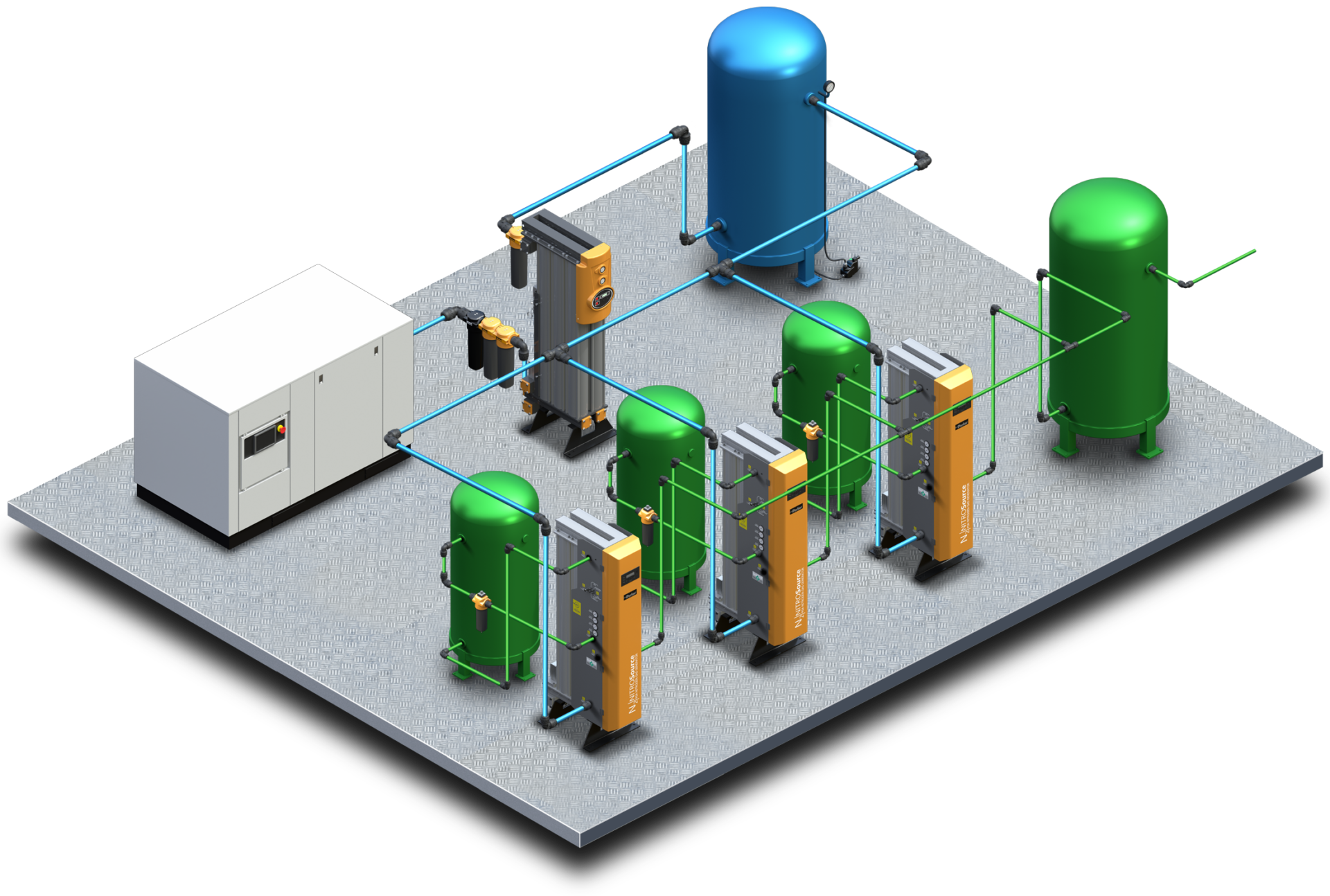

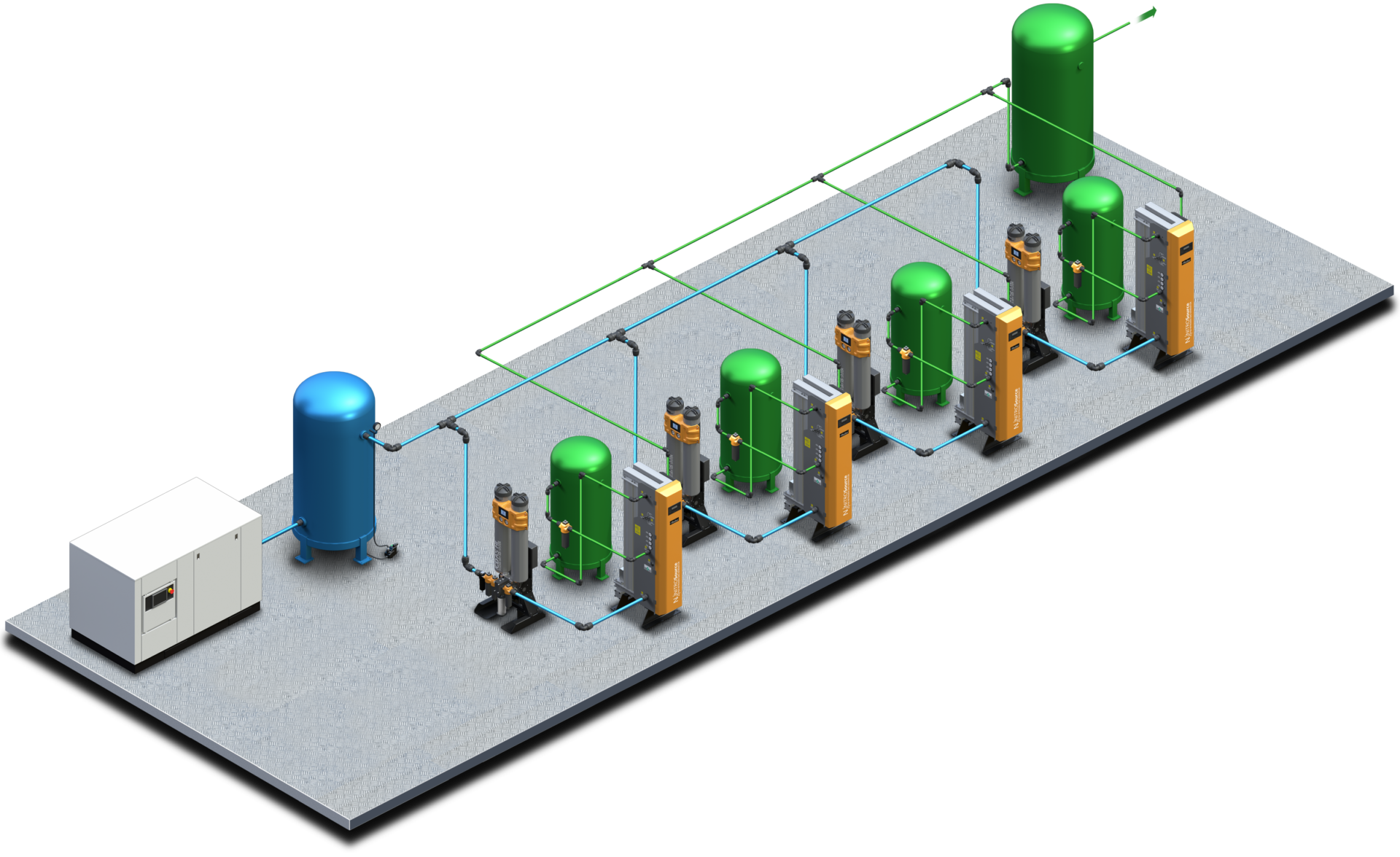

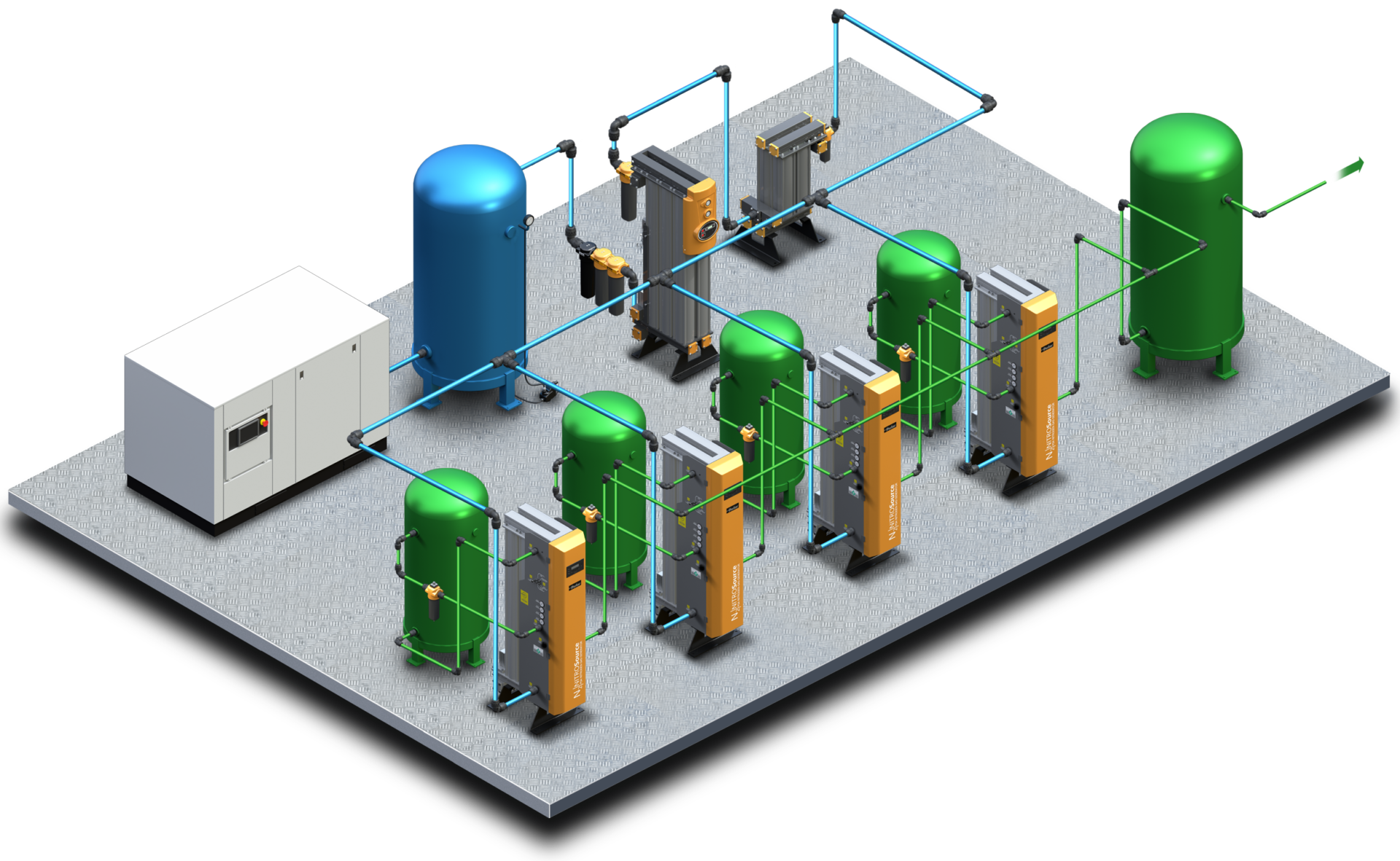

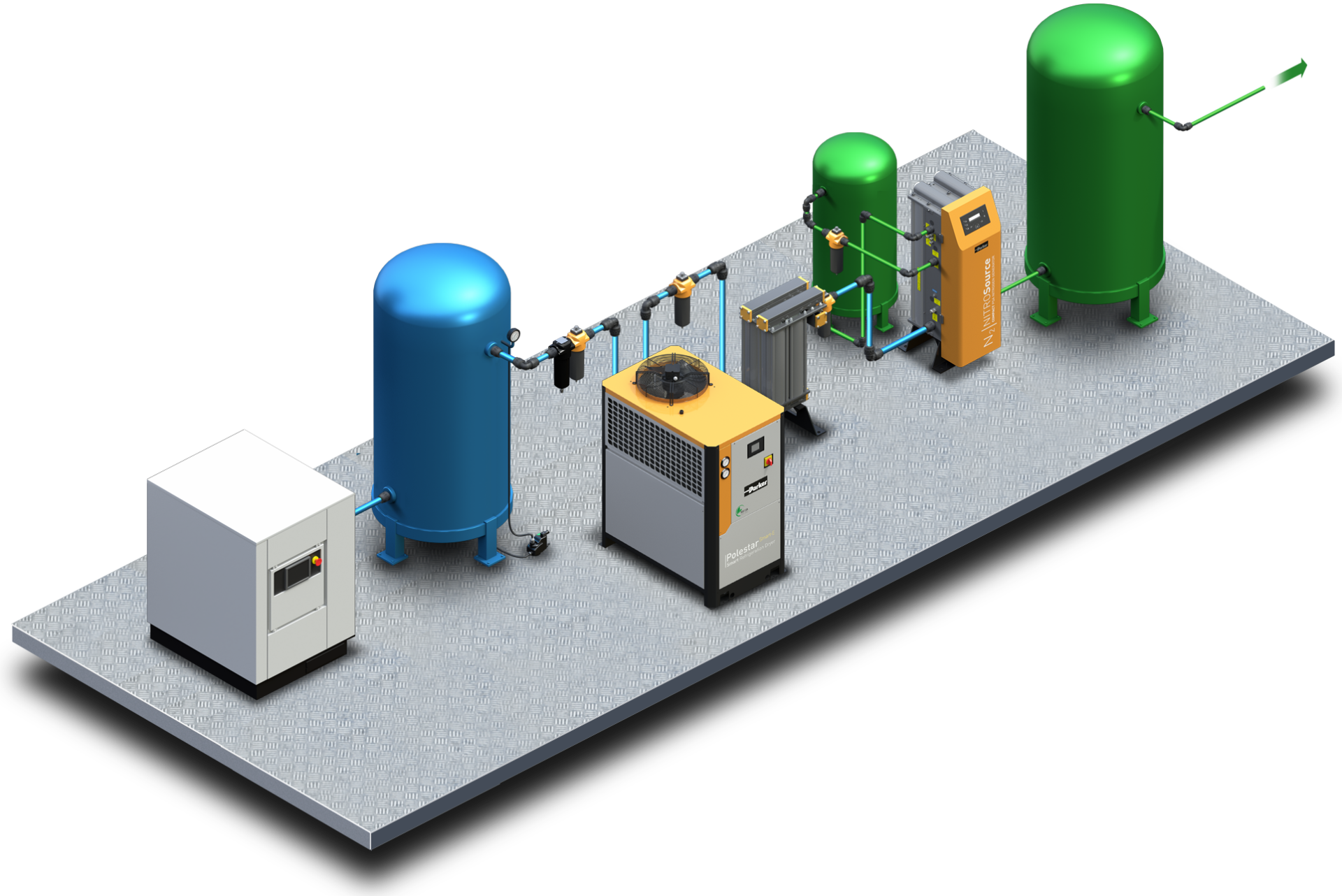

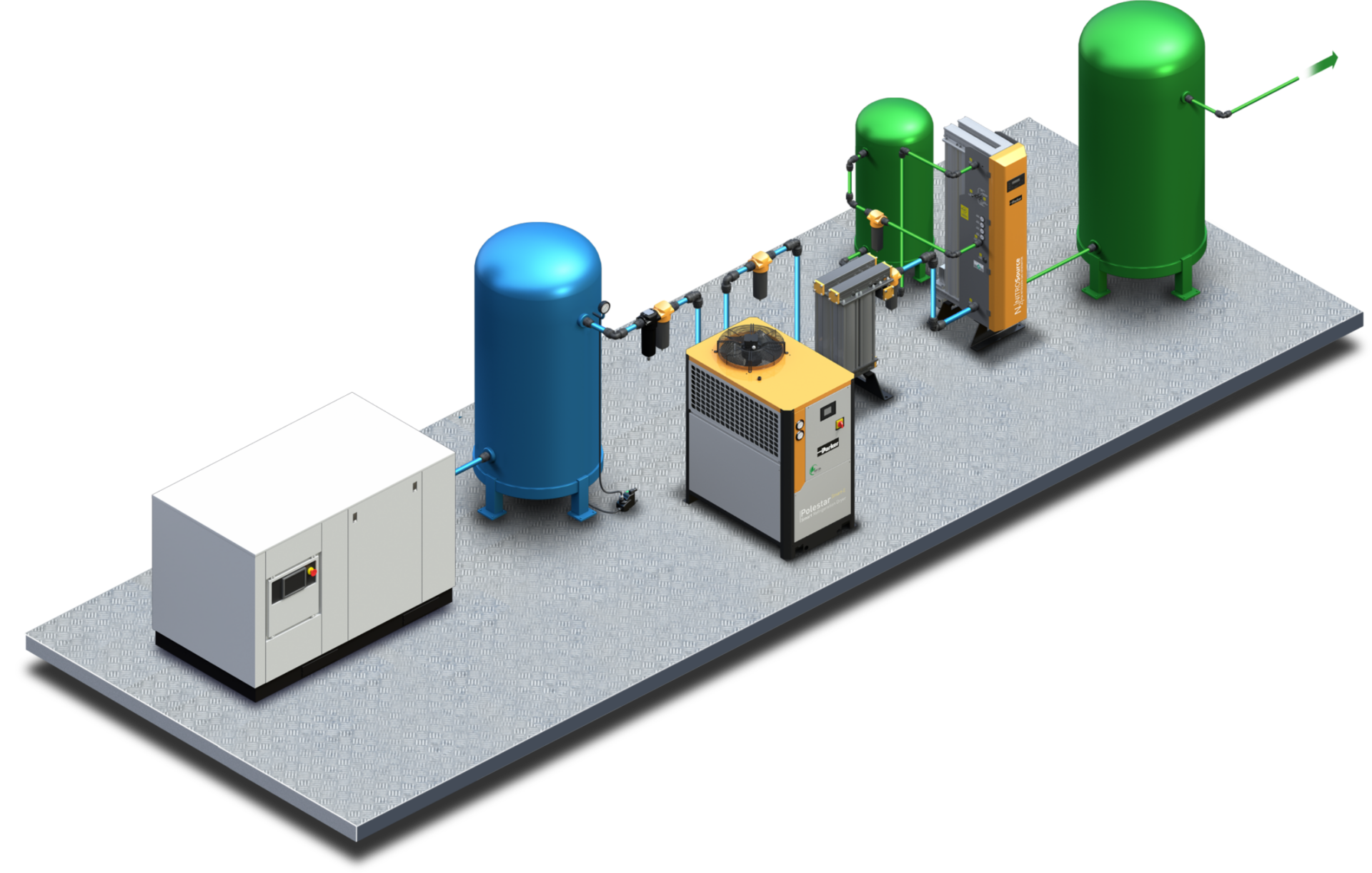

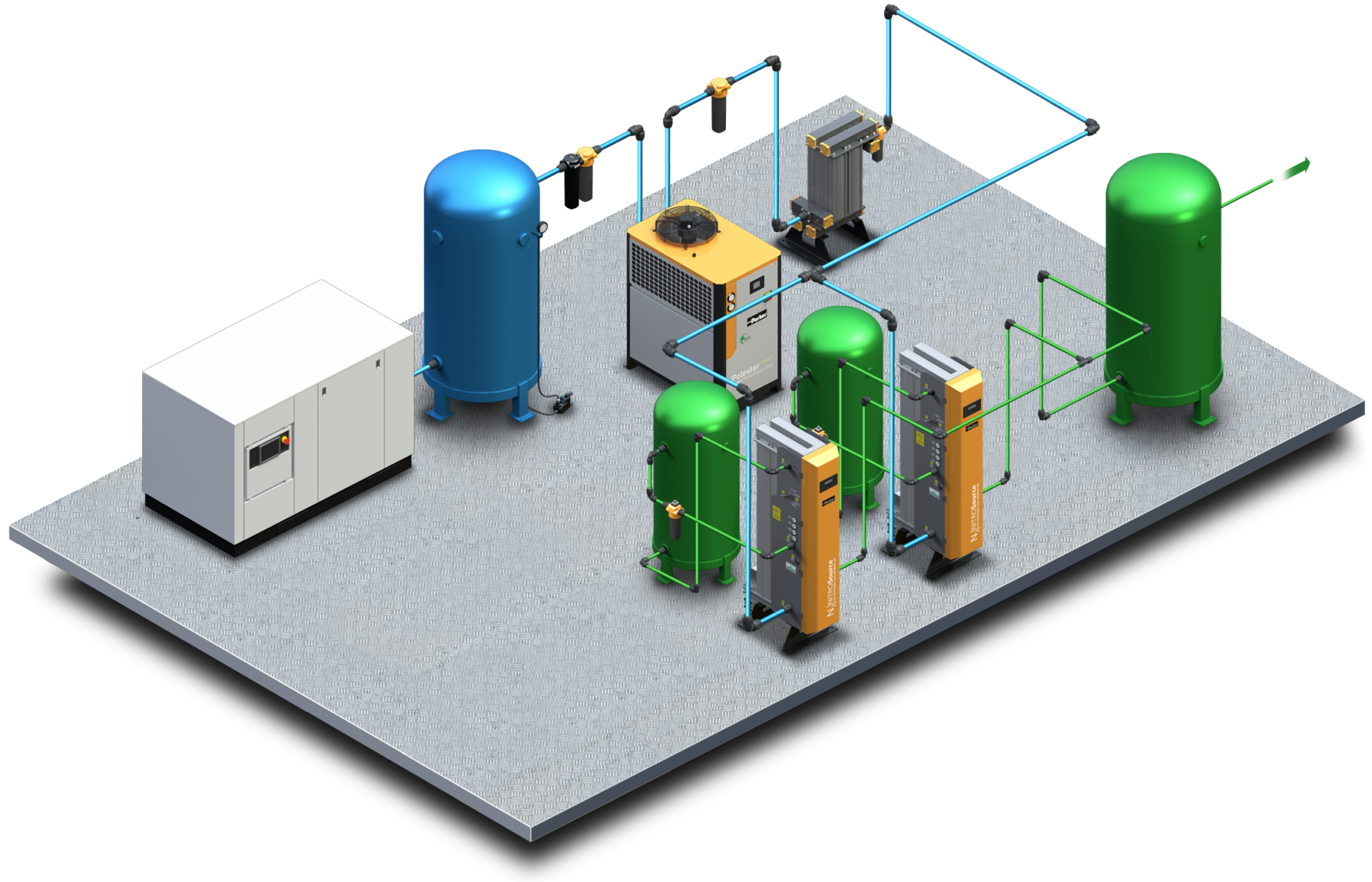

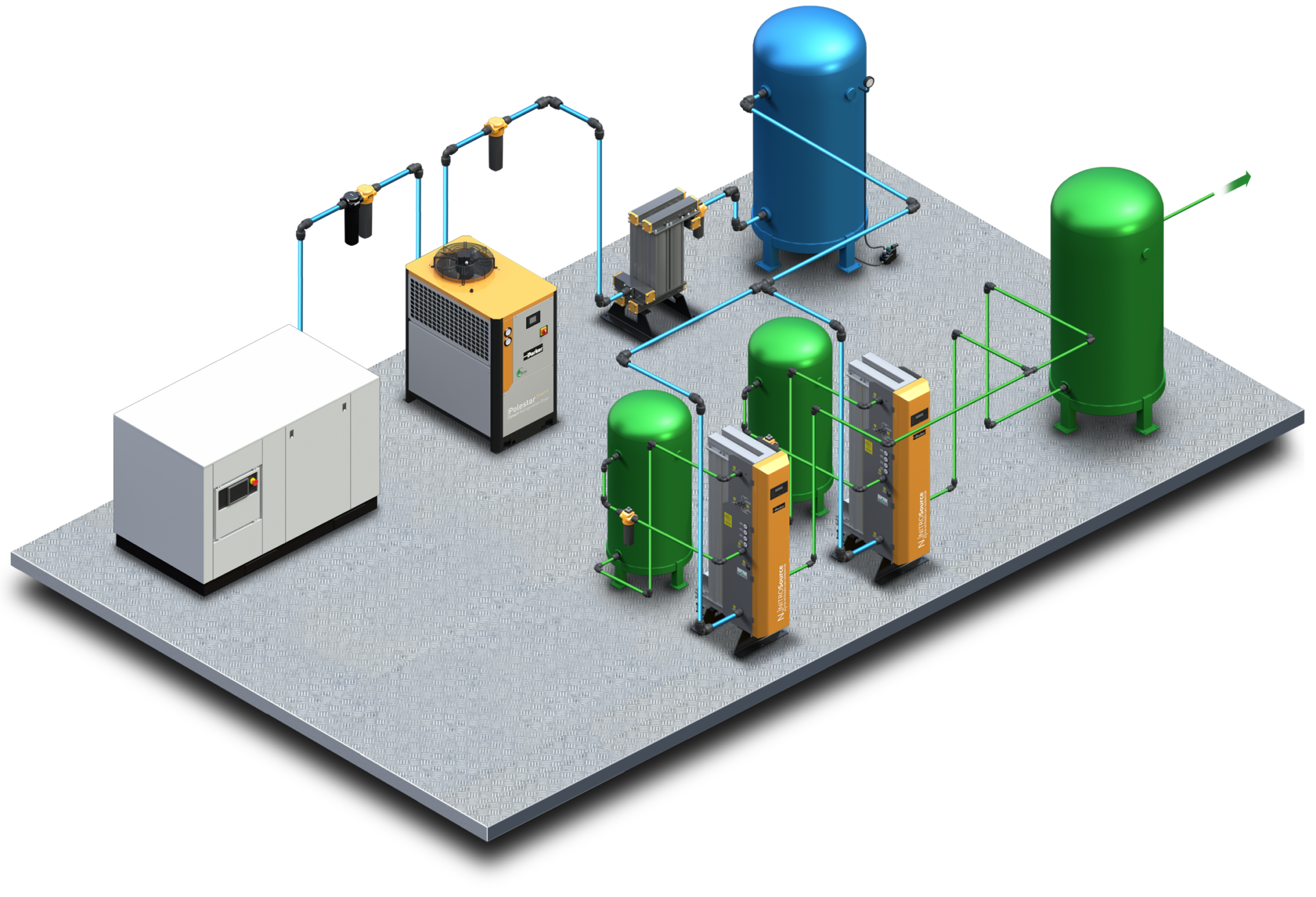

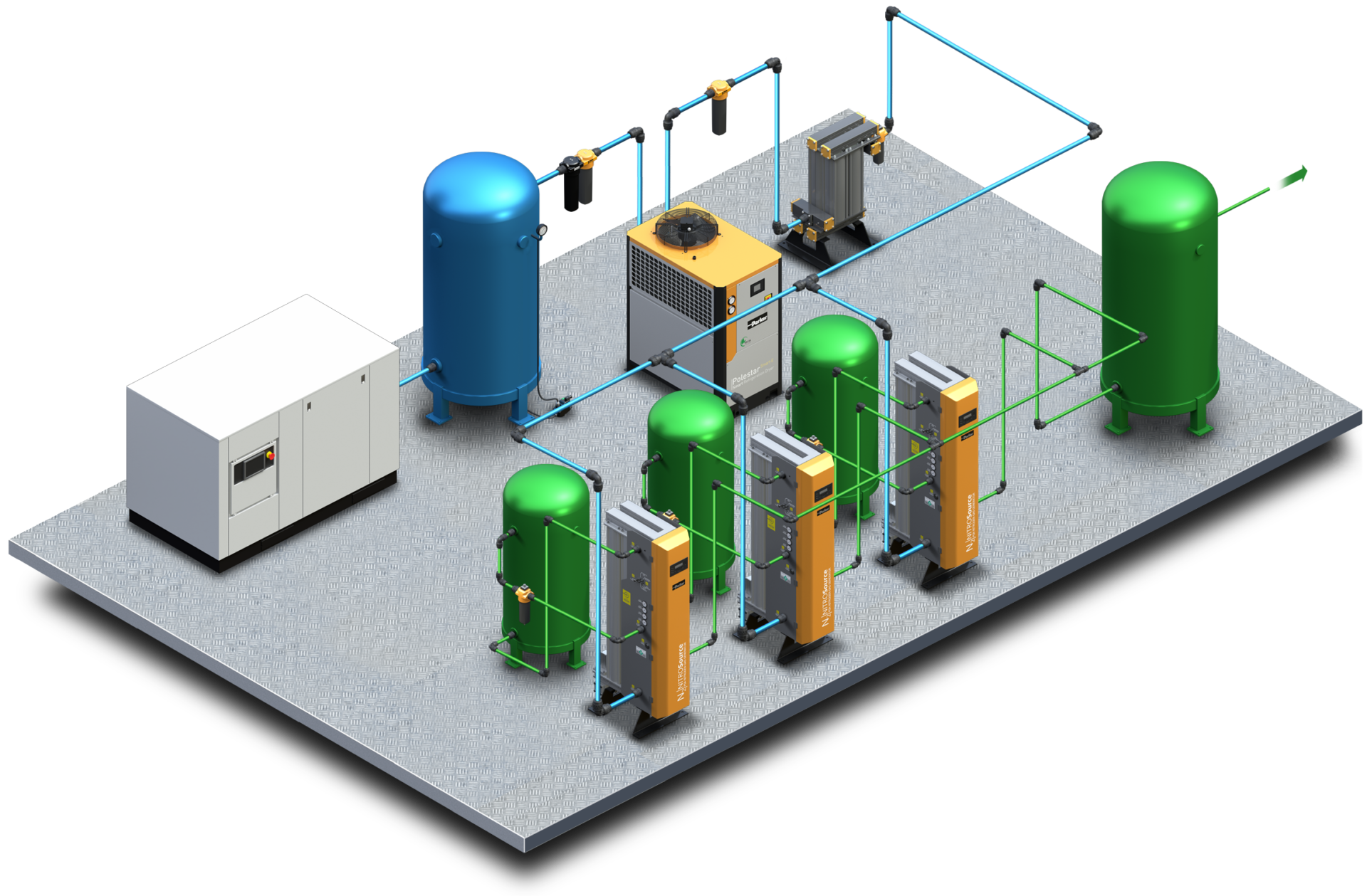

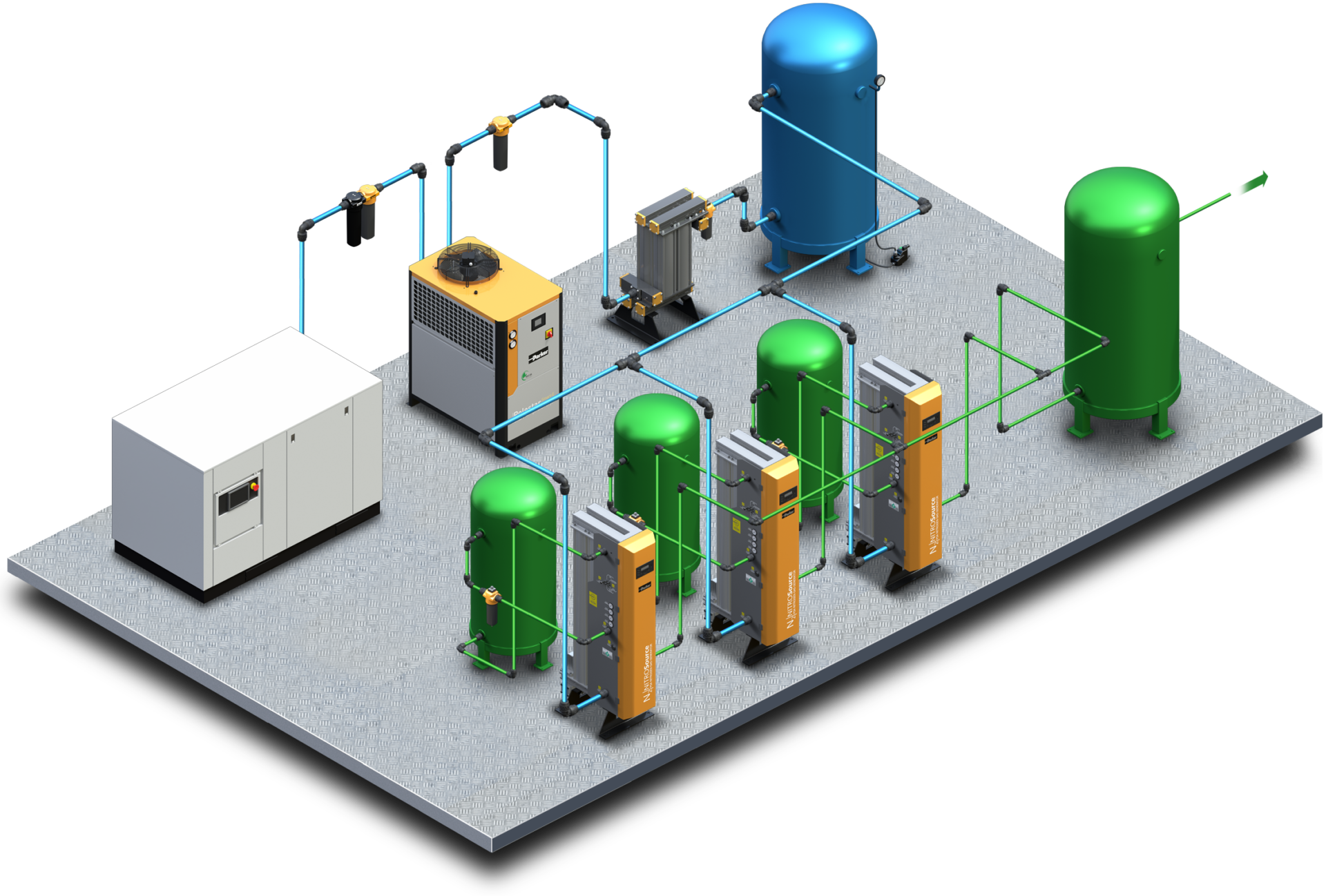

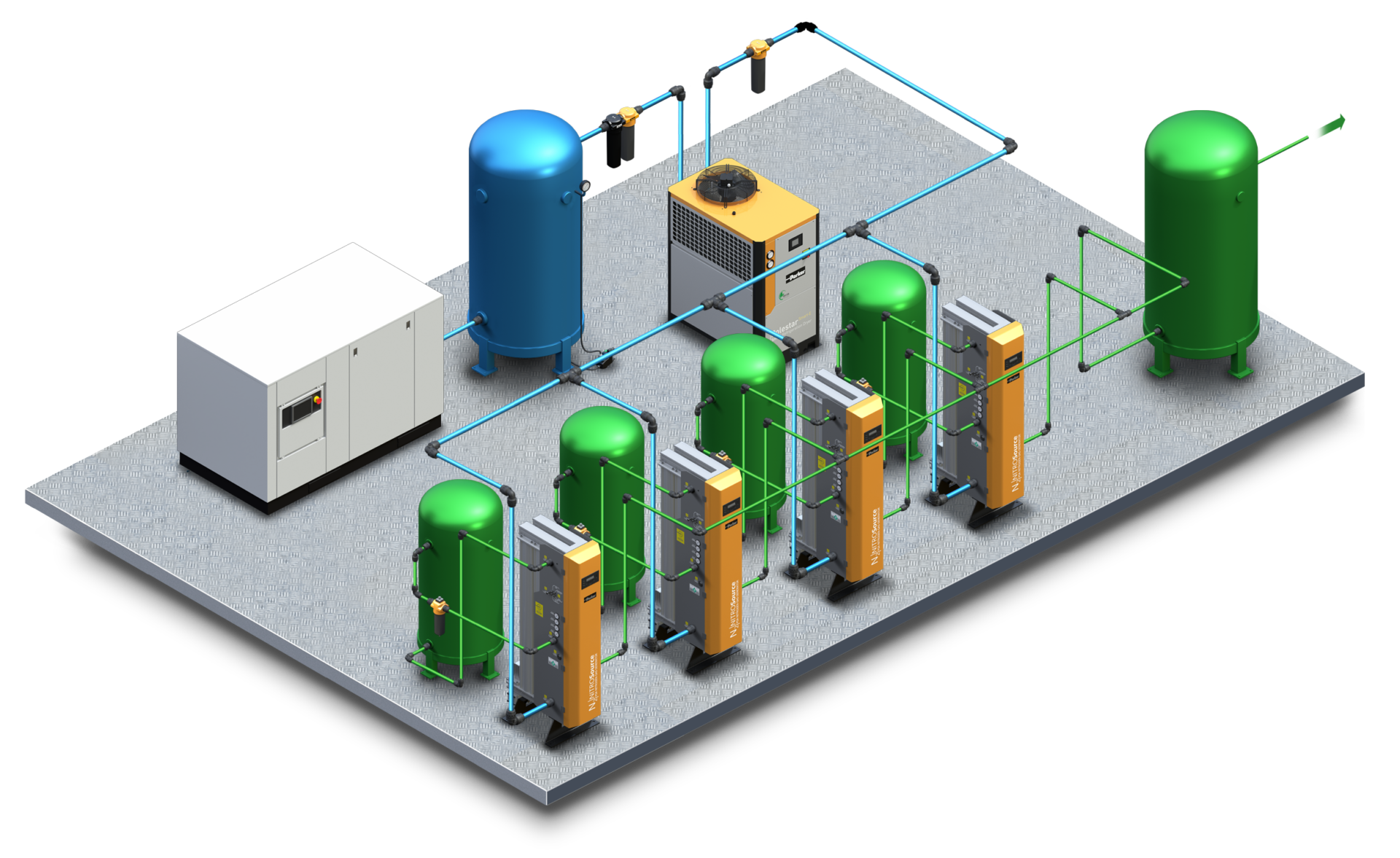

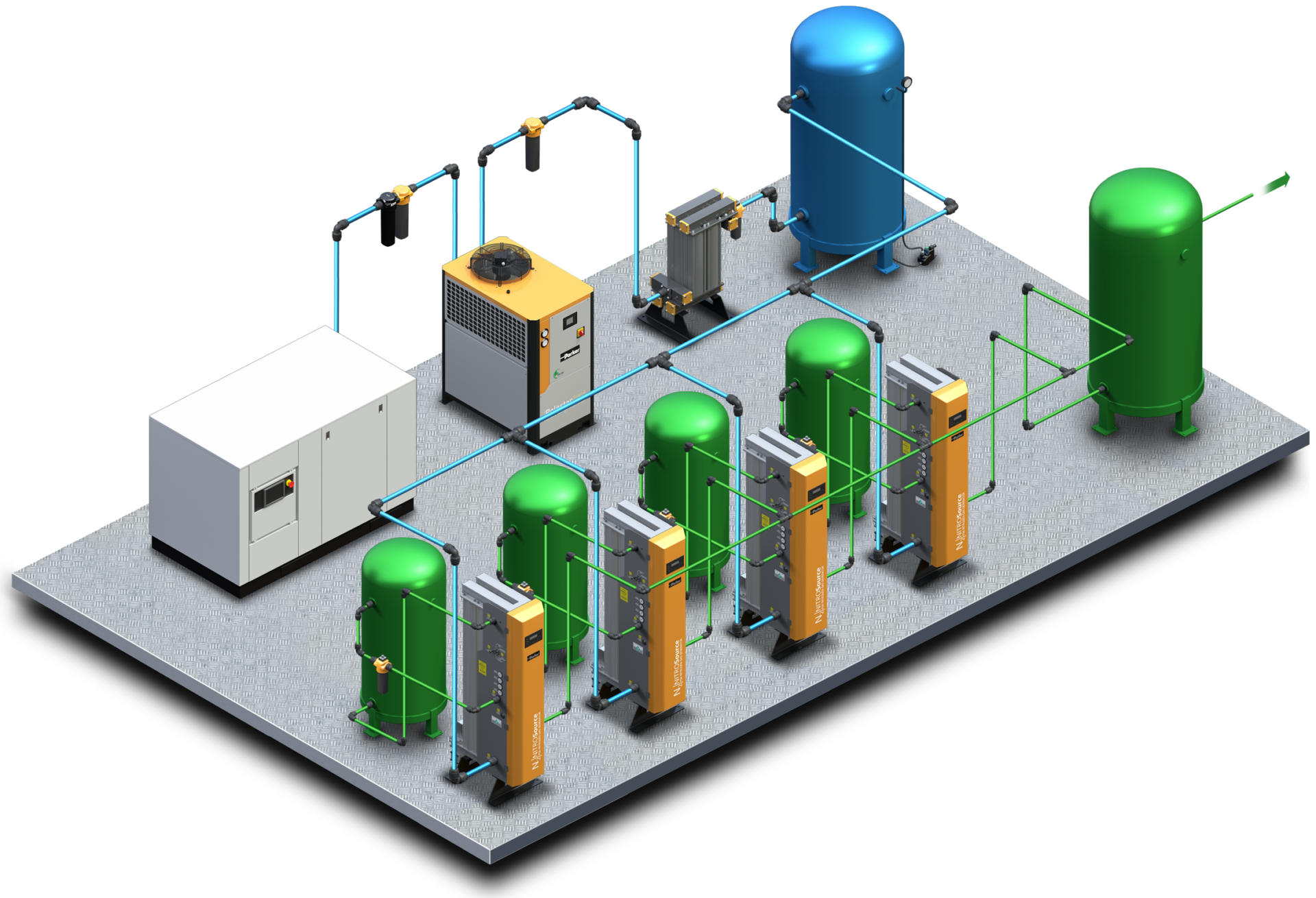

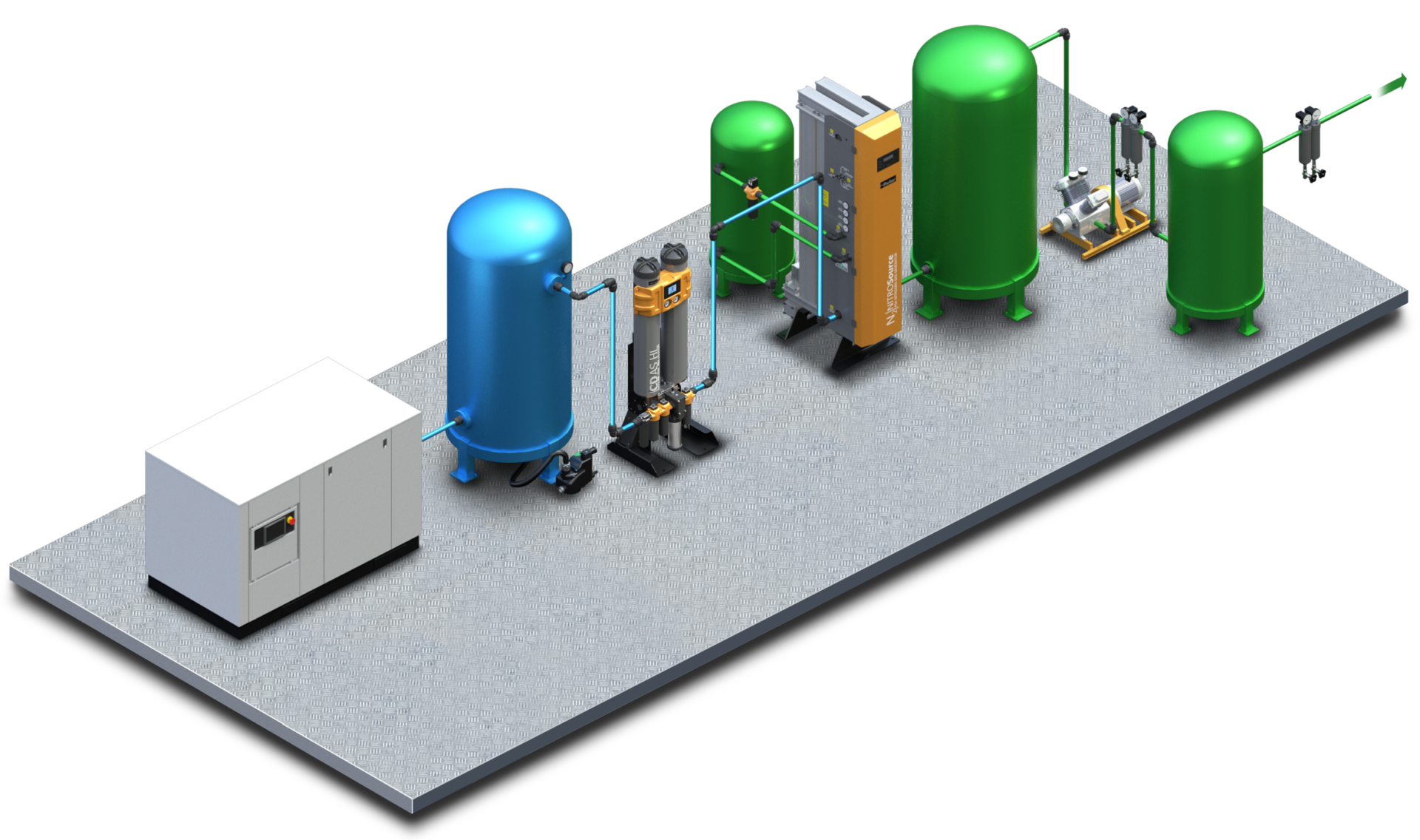

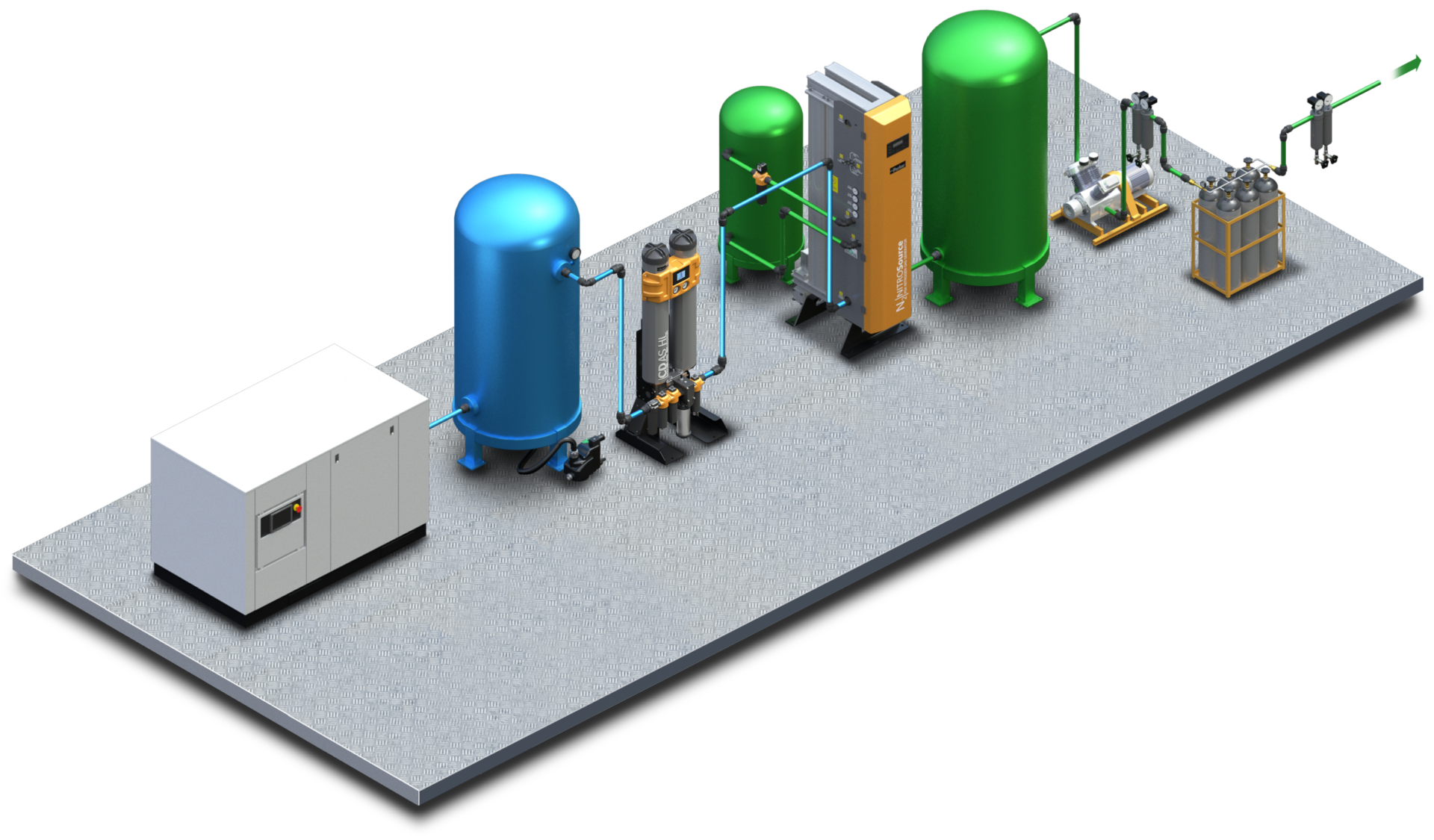

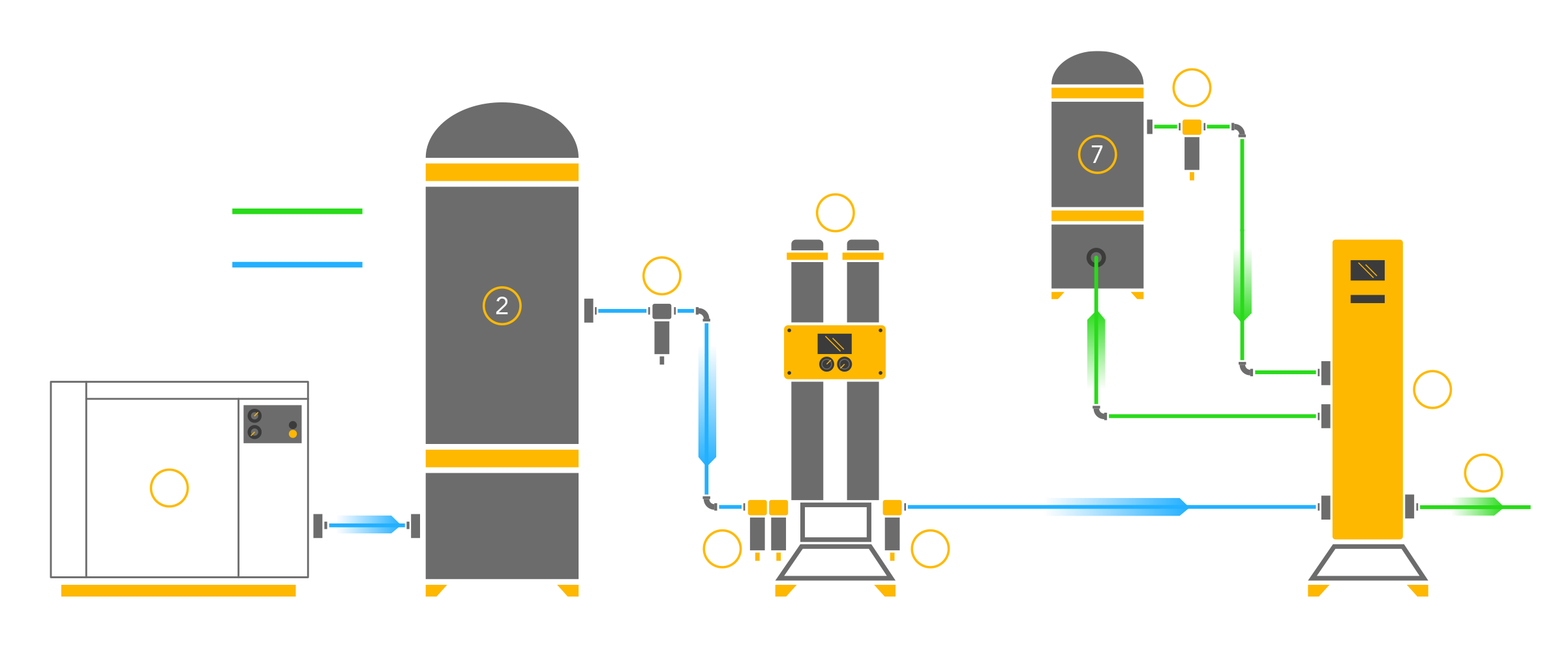

Recommended System Component Layout

OFAS or OVR grade activated carbon filtration recommended and is required for operation above 35°C