NitroSource Features

- Independently certified food grade nitrogen gas to EU statute as a food additive E941.

- Complete control over gas supply and costs with savings often exceeding 70%.

- No unexpected price rises.

- No more expense incurred monitoring gas levels, managing supplies, running out and waiting for deliveries.

- No gas wasted through boil-off or part full cylinders sent back to supplier.

- Constant flow and pressure delivered 24/7 ensuring maximum up-time.

- Operates from standard factory air compressor.

- Fully automatic operation and control, practically fit and forget.

- Energy efficient – matches minimum compressed air consumption to meet Nitrogen output.

- Sustainable long-life technology, environmentally friendly, reducing CO2 emissions.

- Very low total cost of ownership with minimal servicing required only once per annum.

- Remote monitoring capability for data logging and traceability.

- MODBUS connection as standard enabling easy BMS integration.

- Compact space space saving design, fits through standard doorway.

- Increased safety without the need to store or handle high-pressure cylinders.

- Unlike bulk liquid vessels there are no large stored volumes of potentially asphyxiating gas.

- Reduced site vehicle traffic and safety concerns over cryogenic tanker movements.

- No manual handling and personnel competence training for very high-pressure cylinder connection.

- Large installed base and extensive within food and beverage.

Modular Construction

KEY FEATURES

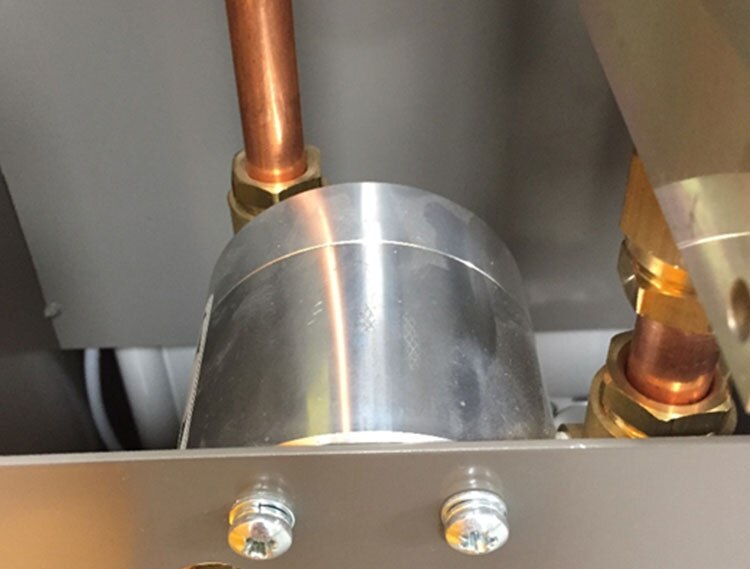

Mass flow controller

The mass flow controller (MFC) is a device that has 3 main functions.

1) To set the nitrogen outlet flow based on the generator specification2) To maintain a stable flow and outlet pressure regardless of down-stream pressure fluctuations3) To prevent the generator from being over-flowed

Unlike flow control devices such as needle, ball, and gate valves for example, that can cause fluctuating outlet flow, due to changes in down-stream pressure.

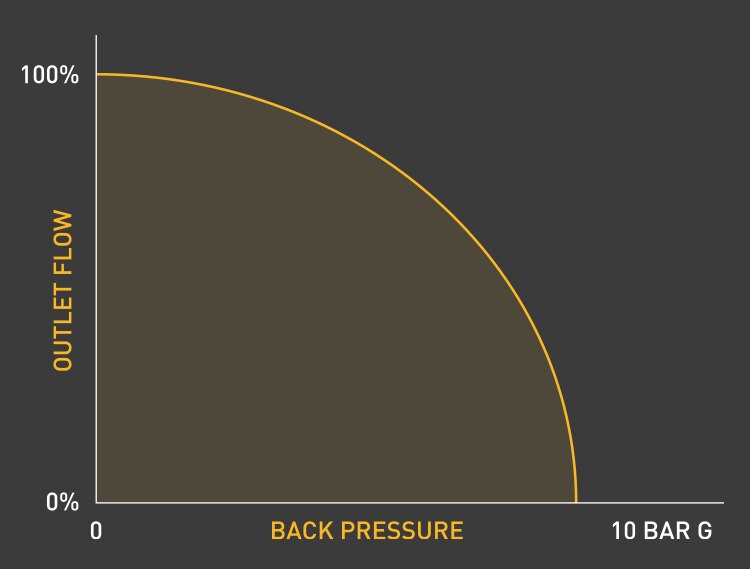

Needle or gate type valve

Unlike Parker’s Mass Flow Controller, if a needle or gate type valve is used to control nitrogen outlet flow, then the flow will decrease as the back-pressure increase.

The mass flow controller maintains a stable outlet flow.

The MFC also contributes to maximum up-time by helping to prevent high oxygen alarm conditions, caused by reduced air/CMS contact, time that would occur when a generator is being over-flowed.

Off gas bypass

The off-gas bypass system is incorporated within the generator outlet valve block and is activated if a high oxygen alarm condition occurs. It shuts off the main nitrogen outlet valve thus preventing out of specification gas from contaminating the application or process.

In addition, a second valve within the nitrogen gas outlet block, opens and vents the out of specification gas contained within the buffer vessel and outlet manifold to atmosphere at two thirds of the generator’s maximum flow setting.

Reducing the flow in this way increases the inlet air contact time with the CMS and facilitates more oxygen adsorption, hence rectifying the high oxygen situation. The off-gas bypass is an automatic feature and usually restores purity without any user intervention.

It is also a useful feature to rapidly achieve purity when commissioning a generator for the first time or when re-starting a generator from lay-up.

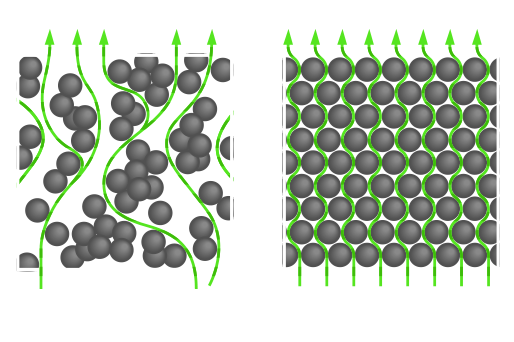

Snowstorm filling

The design of the columns enable a filling process for the CMS called snow storm filling. This ensures maximum packaging density to prevent the sieve bed moving and leaving leakage paths.

The advantages gained by using snowstorm filling are:

The CMS bed cannot settle. This prevents CMS granules from rubbing together and wearing away (attrition), which reduces the life of the CMS and requires constant topping up.

There are no leakage paths for the compressed air to find, so all of the CMS is utilised. This gives a very stable performance with maximum efficiency whilst reducing the overall amount of CMS required.

Integral oxygen analyser

NITROSource PSA and NITROSource Compact models incorporate an integral oxygen analyser to constantly monitor the purity of the outlet nitrogen gas stream.

The oxygen content is displayed on the controller screen either as a percentage (%) or a parts per million (ppm) value depending on generator specification.

The oxygen analyser is linked to an alarm function that indicates high oxygen content locally as well as volt free contact for remote monitoring. Included also are 4-20 milliAmp outputs for remote oxygen indication, with MODBUS contacts able to show this remotely too.

Economy control

- Pressure transducer controlled in 0.1 barg increments

- Stops generator when no nitrogen is required

- Shuts off air consumption

- Zero energy used for compressed air

- Starts generator when pressure drops, indicating application is demanding flow.

ENERGY SAVING TECHNOLOGY EST

In addition to economy control, NITROSource PSA generators, within the purity range from 50 ppm to 5% maximum remaining oxygen content, can incorporate Energy Saving Technology EST.

EST is a Parker developed program that uses an additional oxygen analyser and PLC board connected to the generator control system. It constantly monitors the oxygen content and adjusts the generator cycle time based on extra CMS bed capacity at part load conditions.

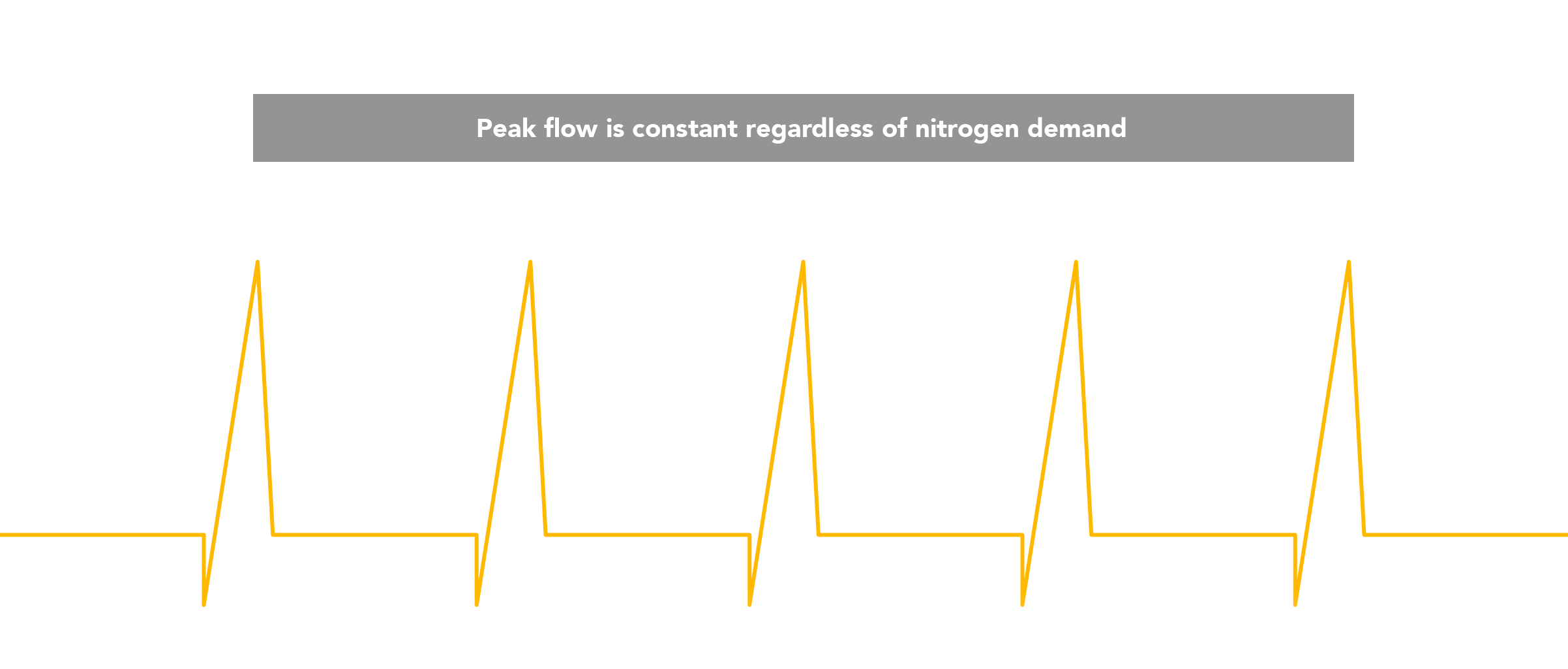

For all PSA nitrogen generators, the point of column or vessel changeover is where the most compressed air is used to exhaust and refill. If the column changeover period is increased, then the accumulative effect is lower overall air consumption.

A fixed timing cycle generator uses almost the same amount of inlet compressed air at part load conditions as at 100% load.

Therefore, the air to nitrogen ratio becomes much higher.

It is important to note that air to nitrogen ratios for fixed timing cycle generators are only accurate at 100% flow!

Fixed timing cycle PSA with same peak air inlet flow every 60 seconds

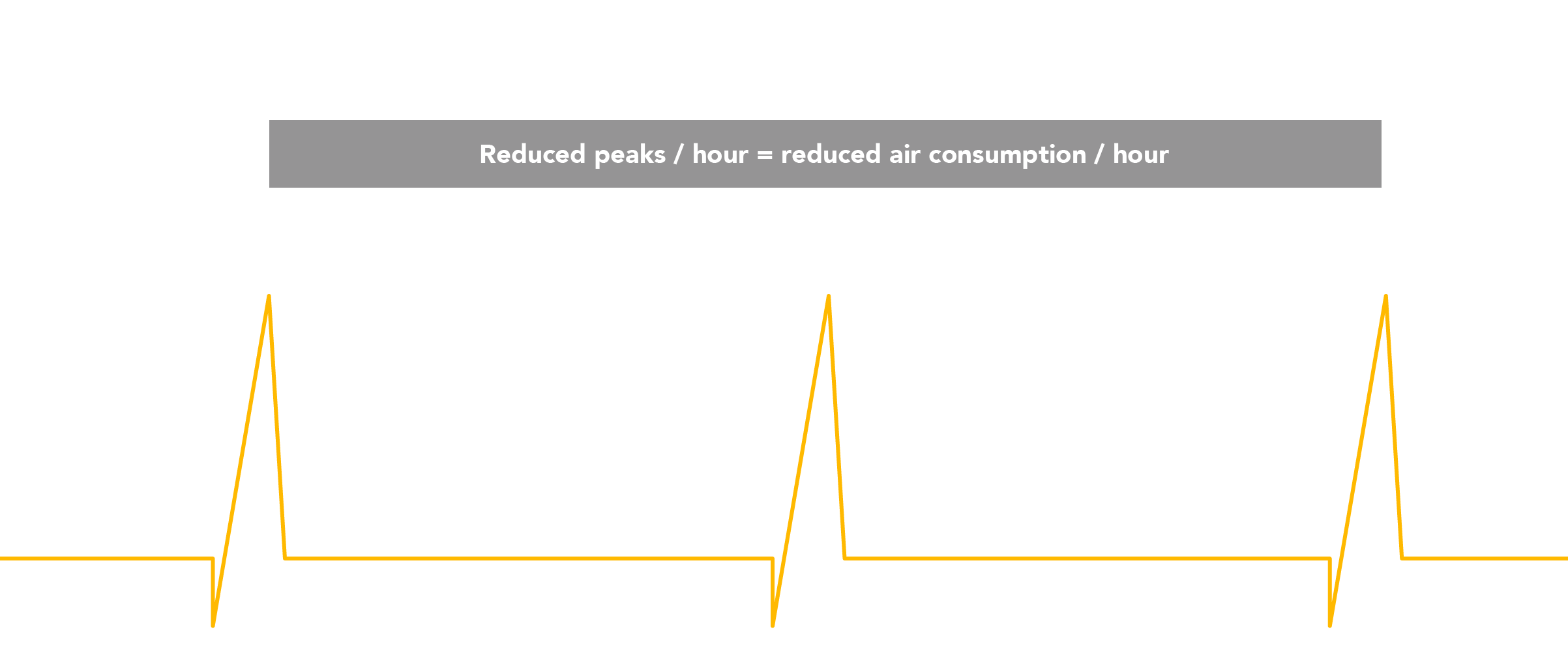

Parker’s EST function adjusts the timing cycle based on outlet flow and reduces the overall air inlet flow accordingly by extending the cycle time between column change-over.

Variable timing cycle, (EST), PSA with peak air inlet flow every 120 seconds at reduced load, for example

Flow demand % |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

55 |

60 |

65 |

70 |

75 |

80 |

85 |

90 |

95 |

100 |

Predicted Average Energy Saving % |

61 |

57 |

53 |

49 |

46 |

44 |

41 |

38 |

36 |

34 |

31 |

29 |

26 |

23 |

16 |

15 |

10 |

Even at 100% flow, Parker’s EST function reduces overall air consumption because it bases cycle time on actual CMS bed capacity, negating any inbuilt sizing safety factors.