HEAT TREATMENT

Nitrogen is used for heat treatment applications, primarily to provide an inert atmosphere within a furnace or oven to prevent materials from oxidising at high temperature.

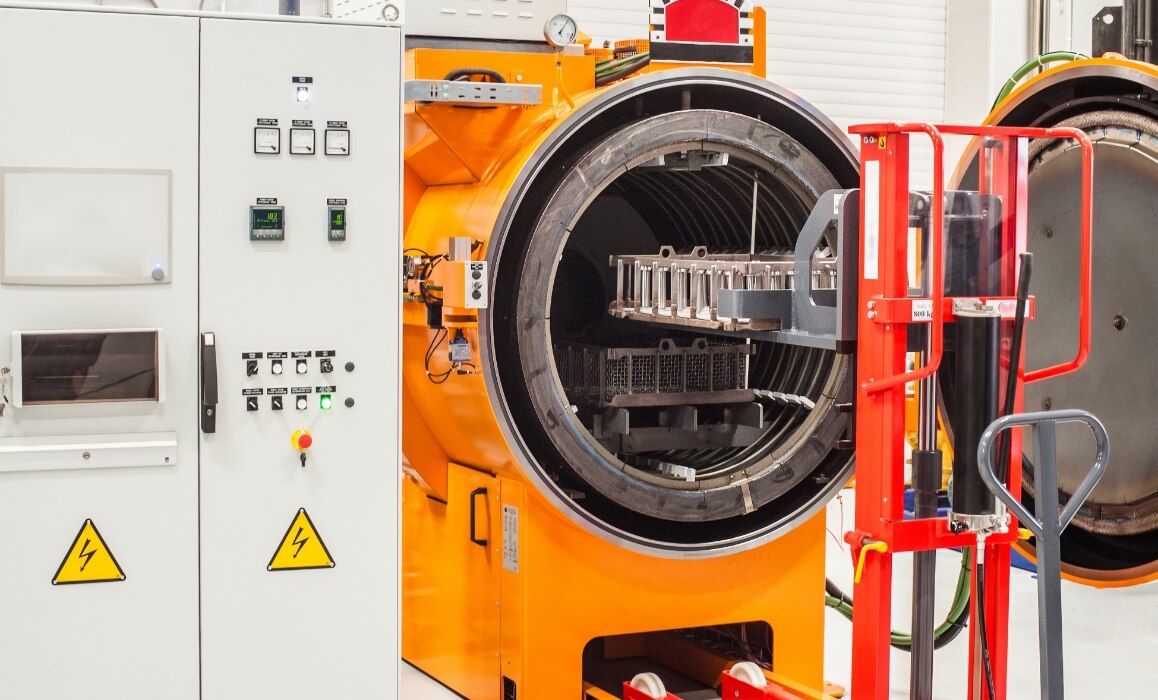

There are many different processes, applications, and oven types. The majority of applications involve the treatment of metals but composite materials such as carbon fibre are cured under pressure and temperature in an autoclave, to set the resin. In this case nitrogen is used to prevent a possible fire within autoclave that could be caused by vapours produced by the flammable resins.

In general, metals undergo treatment by the application of heat to change their molecular or crystalline structure to make them harder or softer or to join components through brazing, depending on the actual product requirements.

For materials such as stainless steel, copper, and carbon steels etc, where a bright, shiny finish is required, high purity nitrogen is normally prescribed, typically <10 ppm oxygen content. Sometimes even such high purity nitrogen is insufficient to provide the correct reducing atmosphere within the oven and other gases such as hydrogen are needed to scavenge any remaining oxygen molecules.