FOOD PRODUCTION

Food products generally start to degrade as soon as they are harvested or manufactured through a wide variety of spoilage mechanisms, mostly microbial or oxidative. Nitrogen is used to slow down the spoilage mechanisms that need oxygen to survive, (aerobic), by excluding ambient air.

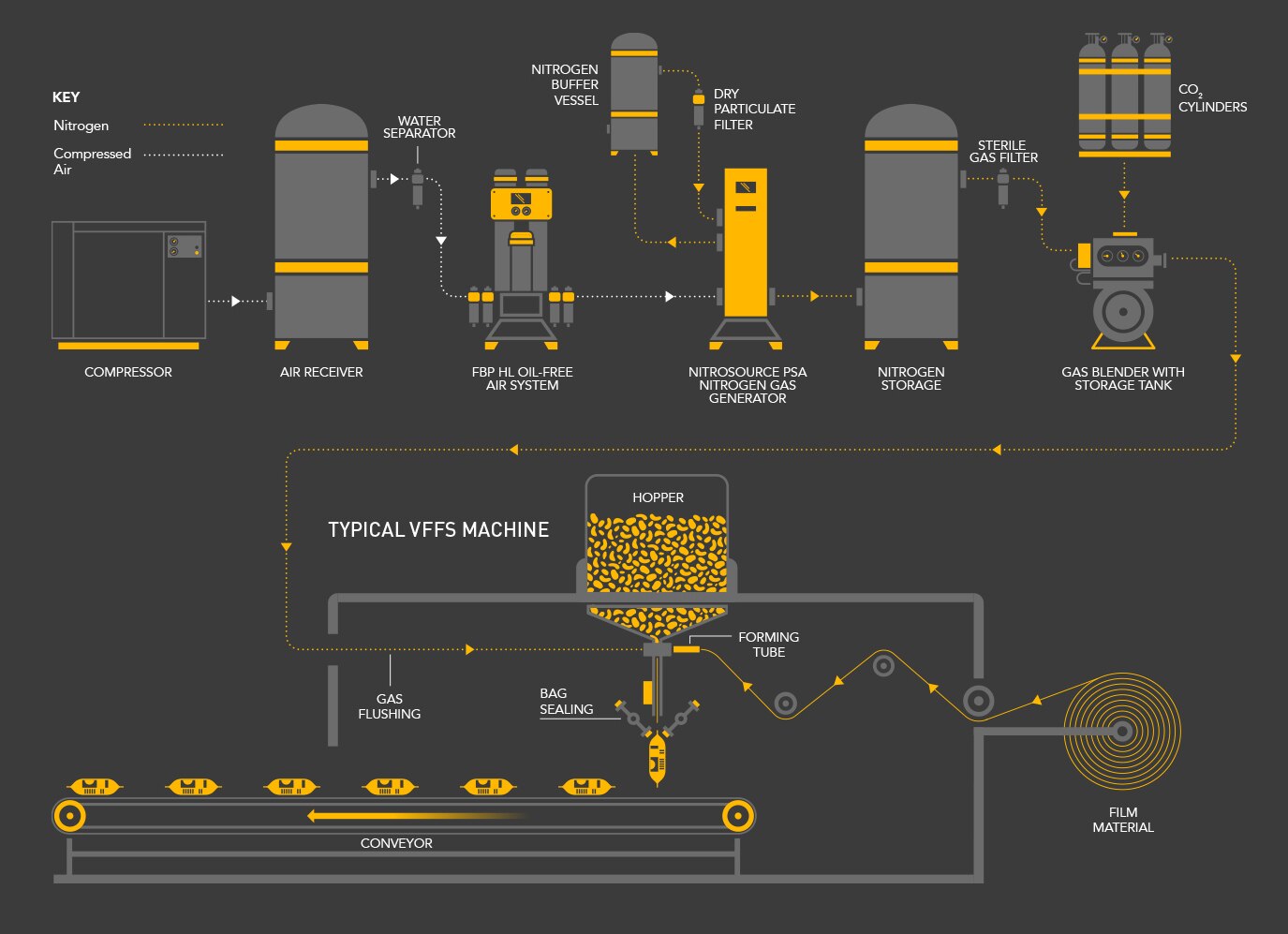

Often nitrogen and carbon dioxide are combined to retard anaerobic spoilage mechanism, with nitrogen used as a filler gas to prevent pack collapse caused by the highly dissolvable nature of CO2.

There are 3 main areas where nitrogen is used in the food production process: