ELECTRONICS MANUFACTURING

Nitrogen is used to blanket soldering processes, to prevent oxidisation, resulting in poor component to board joint properties and failures.

There are three main types of soldering process:

For Illustrations with markers, the best experience is on a larger screen.

CLOSE

Nitrogen is used to blanket soldering processes, to prevent oxidisation, resulting in poor component to board joint properties and failures.

There are three main types of soldering process:

Through the hole components are individually or collectively soldered by a continuous jet of solder contained within an inerted nozzle.

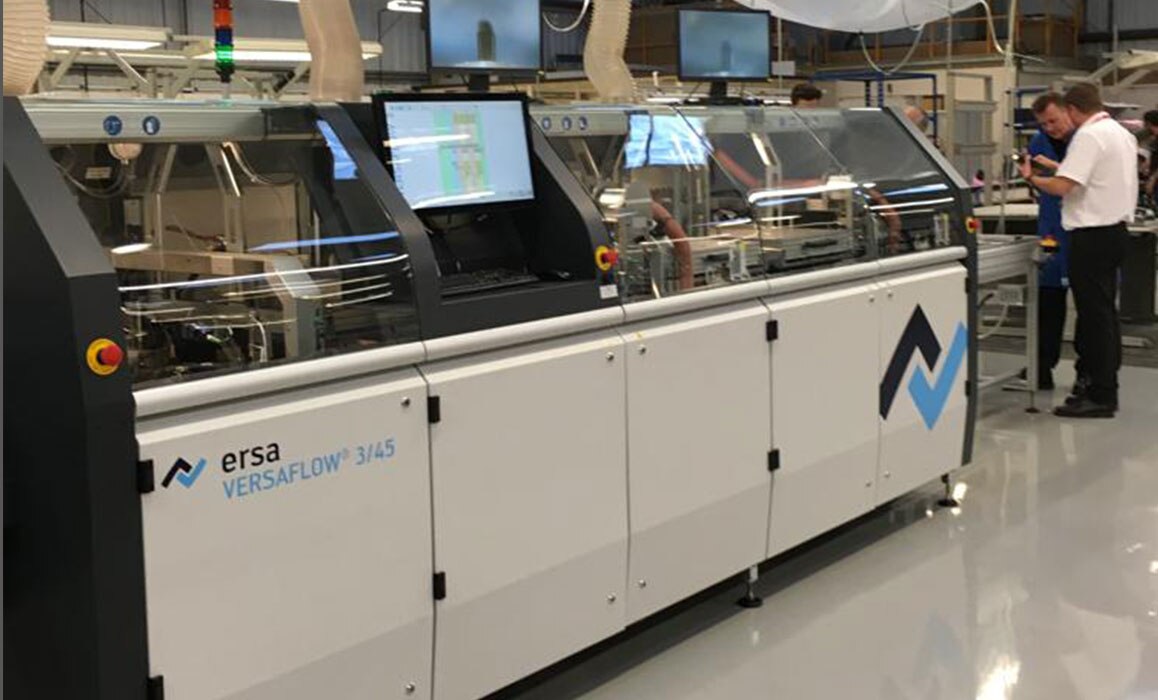

A printed circuit board is transported over a solder “wave” to solder all of the components in one operation.

Re-flow soldering – is where printed circuit boards with normally surface mounted components fixed in place with a flux/solder paste, are fed into an oven on a continuous loop conveyer or specific PCB carriers. The oven has heating and cooling zones to control the stress on the components and boards.

In addition to the soldering processes, nitrogen is also used within inert storage cabinets/rooms to prevent sensitive electronic components from moisture and oxidation. Nitrogen is also used of for the production of integrated circuit components (ICs), as well as laser ablation.